This site contains affiliate links. As an Amazon Associate, I earn a commission from qualifying purchases at no extra cost to you. Full Disclosure Here.

The grind of a blade on a new knife is an extremely important, albeit often overlooked, characteristic among many other characteristics that, simply put, if you don’t understand, you are likely to find yourself with a suboptimal product. In this guide, we’ll talk about the various knife grinds available to you, what their pros and cons are, and where and why you would choose one grind over the other.

Keep in mind there is no “best knife grind” just as there is no best knife steel, best knife blade shape, or best knife handles (all of which we have guides on too). When choosing a new knife, there are a bunch of characteristics, knife grinds included, that are going to determine how that knife handles and behaves in specific circumstances, so it’s important to take a long walk and really ponder how you plan on using your future knife.

Buying a new knife is kind of like buying a new car. There are so many manufacturers, options, characteristics, colors, and new gadgets you get to choose from, and to many, it may seem like a daunting task to choose one out of the myriad of choices available to you.

If you ask for the opinions of others you will almost never get a well thought out comprehensive answer but more so a heavily biased and uneducated recommendation of something that person simply has used before and didn’t have much issue with, but is that recommendation based on what YOU need or what THEY need? Of course not, most people that drive cars and/or operate knives do not have comprehensive knowledge of each and every attribute that sets the options in those categories apart.

Choosing a knife to the untrained eye typically comes down to what looks cool, but if you appreciate learning about your tools and making fantastic choices instead of subpar choices, and we know you do because you’ve chosen to visit our website as opposed to our competitors, then you’ll find yourself with a knife that you may forge a strong relationship with for many years to come.

What is the Grind on a Knife?

The grind is a characteristic of the blade that determines its shape, thickness as it approaches the cutting edge, and technique used to finish the blade. Before the blade receives its respective grind type, it’s really just a block of metal in the shape of the final product but it has no tapering and thus doesn’t come to a sharp edge.

To achieve sharpness on a blade’s edge you literally have to cut and grind into the material and remove a significant portion to achieve a shape that we can put a sharp edge on, but how we go about this is heavily debated with many different techniques and styles. If you’d like to see how a knife blade receives a grind, check out this video from the Green Beetle Youtube channel!

Why is the grind of a blade so important in my decision for the next addition to my knife collection?

Just like the many other characteristics of a knife, the different types of grinds are certainly not created equally but they are created with a use case in mind. The grind your blade has will determine its ability to behave in a manner the knife was intended to be used in.

Some grinds will lend themselves to being especially fantastic in the slicing department but may lack the structural integrity to be used around the campground. Other blades may be thick and strong, making them very useful for chopping, hacking, slashing, and even penetrating body armor in some cases, but may leave your attempt at making clean slices from a tomato more like making tomato mash.

Of course, like most things in life, there is a rather wide middle ground where there are several types of blade grinds that, although they can tackle many tasks and make for exceptionally versatile tools, lack the precision or heftiness to really stand out in any particular category but are more so great for when you have no intel on the next task your knife will face.

As a last tidbit here, the different grind styles may require different sharpening techniques and attention to maintenance. As mentioned before, there are quite a bit of performance and durability differences between not only the steel the blade is made of and what shape the blade is formed into but the grind it has as well which will change how the knife behaves, how it holds up during abuse, what materials it excels or has trouble cutting through and how long it can be used effectively before needing to be sharpened.

You can learn a bit more about knife grinds from this interview with professional bladesmith Jim Crowell.

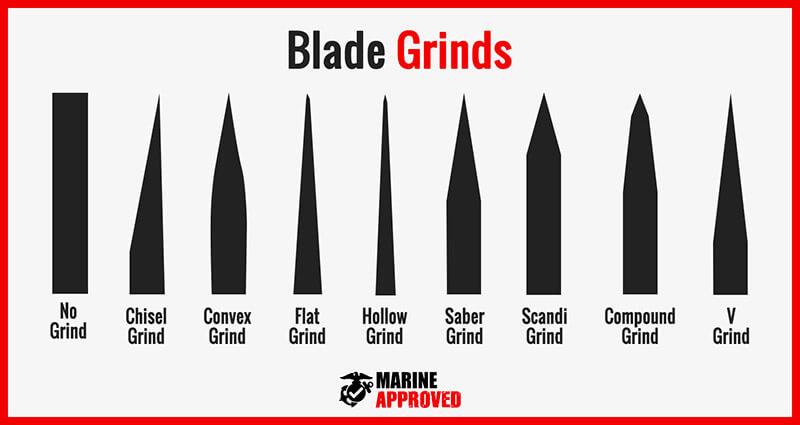

Knife Grind Guide – The 9 Knife Grinds You Need to Know Before Buying a New Knife

A quick note before we get started, we will be listing all of the names of blade grinds you are likely to find while shopping but some of these will be the exact same as others or sometimes interchanged with one and another due to being very similar. I will indicate grind names that are similar to others but we are listing all of them as separate names to make it easy to find what you’re looking for if you come across something specific while shopping for knives and want to learn more about it quickly.

Some of these grind names may also include other terms, for example, sometimes asymmetrical grinds are just signifying any grind that isn’t the same on both sides, which could be used in tandem with another grind term like the chisel grind.

Here Are the Different Types of Knife Blade Grinds

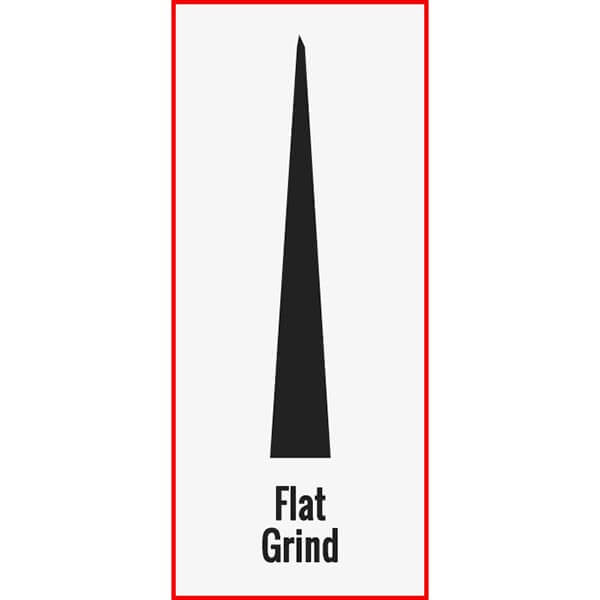

1. Flat Grind (AKA Full Flat Grind or High Flat Grind)

Description: A flat grind can be easily described as the shape of a perfect triangle and is among the easiest to achieve during manufacturing. The linear tapering is consistent from where its initial bevel starts to where there will be a slightly more narrowly ground edge right at the cutting surface. A flat grind will encompass no convexity or concavity and will appear visually flat as well.

There can be a little confusion in the terminology as they are loosely used and often interchanged with one another. If the tapering starts at the very top of the spine, then it’s called a full flat grind although many people may just refer to this as a flat grind. Sometimes you may hear the term high flat grind, which means the flat grind begins after a bevel that’s very close to the spine although there is no official distance used in the industry.

To make matters even more confusing, Scandi grinds and Sabre grinds are also considered to be in the flat grind family but we’ll talk about those separately.

A lot of the performance found in a flat grind comes from the idea that they allow precise cuts without any wandering or steering. This isn’t always true as there are a few other attributes to consider but for the most part, flat ground blades make for excellent kitchen or food prep knives and can be used for skinning or general EDC purposes as well.

Common Use Cases: Since flat grinds can be both thick or thin depending on the style and manufacturer, flat grinds can be found on many different types of knives across many different use cases. A flat grind on an already extremely thin blade is going to make for an excellent slicer while a flat grind on a blade that’s relatively thick will make for a good general EDC purpose blade or perhaps even a survival or camping blade.

Almost all general-purpose kitchen knives are going to be a type of flat grind due to their ability to have a decent level of strength while sliding through most food very easily.

A lot of whittling and woodworking knives are using a thin full flat grind.

Pros:

- Has more precise control than a saber grind and is also stronger than a hollow grind, a bit of a middle ground between two other great grind types

- Is one of the most versatile grind styles, meaning it can host a myriad of blade types and designs and can host both good slicing or good chopping properties depending on the thickness

- Flat or full flat grinds are generally known as great all-around grinds with middle of the pack attributes across the board for the most part

- One of the easiest grinds to achieve in manufacturing thus being one of the cheaper options too (although these can be found on premium knives which will be expensive regardless)

Cons:

- Doesn’t make for the most durable edge or the most overall blade strength

- Easy to maintain but after a lot of sharpening can lose their edges bevel

- Not especially great for batoning or chopping unless made to be very thick

- Flat grinds perform well when given a purpose, meaning if they aren’t especially thin or thick, they end up lacking direction and don’t perform particularly well in any category

Marine Approved Example: Spyderco Delica 4 Flat Ground

2. Saber Grind

Description: Saber grinds have become massively popular as of late and for good reason! They’re very versatile and they often look just as good as they perform. Saber grinds, sometimes spelled sabre grinds as well, consist of having a flat initial bevel, usually totally unground or just slightly ground, that leads into a secondary bevel that generally looks a lot like a flat or hollow grind.

These knife grinds are mistaken for other types of grinds all the time and to be honest, you shouldn’t feel guilty if you call it one or the other because, at the end of the day, they are extremely similar aside from the terminology. Saber grinds are often dubbed as V grinds as well, although we’ll cover those in a separate section because sometimes there are subtle differences between the two.

So what do we call a saber grind who has seemingly lost one of its bevels? We call that a Scandinavian grind and we’ll talk about that later in this guide as well, although beware, sometimes you’ll see the two terms mistaken for each other.

Common Use Cases: Saber grinds sound pretty cool as it rolls off the tongue and that’s quite fitting because we see a lot of tactical knives as well as combat knives and camping knives utilizing a saber grind style for their blades. The reason you’ll see a lot of saber grinds on tactically designed knives is simple, they provide a high level of strength and durability while maintaining a shape that is extremely versatile, allowing the blade to perform well in chopping, batoning, hacking, slashing, penetrating, and general use cutting.

These grinds lend themselves especially well when you need to separate materials that aren’t easily cut where a wedging technique is used.

Saber grinds won’t exactly make for the best slicers, food prep, or super technical and precise usage but they can certainly be used in almost all of these cases with little drawbacks which makes the saber grind extremely versatile and very appealing to many of those who only buy and/or carry a single knife. This makes saber grinds quite popular in a wide range of blade designs and makes them very handy for EDC applications.

Pros:

- These grinds can be used in a myriad of different ways across almost every different category of knife

- One of the most versatile grind styles

- One of the most popular grind styles

- Can be very strong and durable depending on the brand and steel used

- Often a favorite among survivalists, hunters, campers, and people that are just generally hard on knives

- Is a rather inexpensive but reliable type of grind with many options available to the bladesmith

Cons:

- Lack precision compared to something like a full hollow grind

- Sometimes weaker but more expensive than a good full flat grind (rarely the case)

- In many cases, a saber grind will have to trade penetration for chopping/wedging performance (this is done by changing the thickness)

- Generally creates a heavier blade than most grinds (this could be a pro or a con depending on what the desired use case for the knife is)

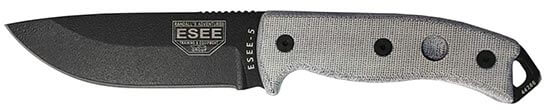

Marine Approved Example: ESEE 5

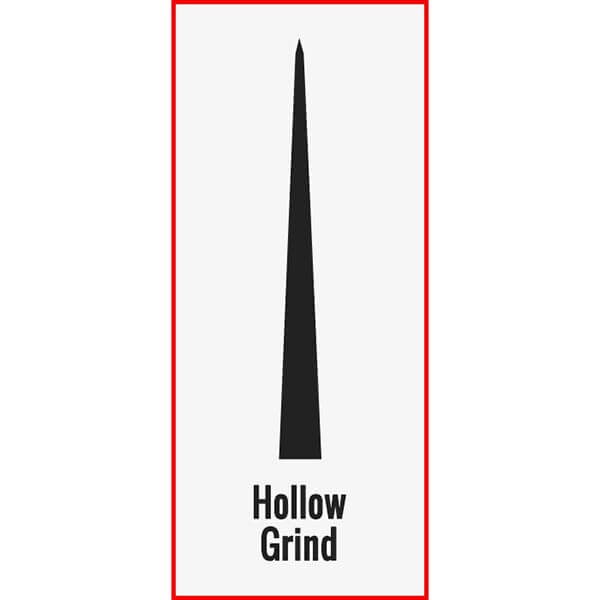

3. Hollow Grind (AKA Concave Grind)

Description: A hollow grind sets the blade up to perform best as a precision slicing machine and it does this by removing a lot of the blade material in a concave shape. Hollow grinds provide for a very thin but razor-sharp edge which is probably why they’re often found commonly on straight razors!

While hollow grinds do suffer from fragility due to simply not having enough material to create strength in the blade and resist chipping or snapping, hollow grinds aren’t meant to be used in tough and demanding situations. A hollow ground blade is going to best suit you when you know exactly what it is you’ll be doing, and those tasks include thin slicing or situations where the blade must be extremely thin, taking out the least amount of overall material from the thing being cut but providing for a very precise cut.

Another big advantage hollow ground blades have is that they resist sticking when used with food or other rather sticky materials due to having much less friction and surface area of the blade in contact with the material being worked with. This makes preparing food a lot faster and easier!

Since hollow grinds typically have very little material supporting the edge, they can be made to be ultra-sharp but tend to lose their edge rather quickly, requiring regular maintenance and resharpening. Resharpening should be easier than most other grind types, though, since there is a lot less material you’ll need to shave off to obtain a sharp edge. Those super thin edges are also prone to rolling and chipping when used on hard and dense materials or when lots of pressure is applied so use them lightly, keep them sharp, and let them glide through soft materials with ease!

You may see terms like “full hollow grind” or “half hollow grind” or even “partial hollow grind”. A full hollow grind is going to be extremely thin with an obvious concave shape starting right from the spine while a half hollow grind may keep the blade relatively thick until halfway down to retain a bit more blade strength and durability. A partial hollow grind, sometimes also called a semi-hollow grind, might mean that only a portion of the blade is hollow ground and the rest is some other type of grind which would qualify the blade to be called a compound grind as well. Partial hollow grinds are also typically referred to when only the immediate area around the edge is hollow with the majority of the blade being thicker and stronger.

As a last note here would be to look out for “saber hollow grinds” as well. We’ll talk about those more down below but as a generalization, a saber hollow grind is basically the same as a partial hollow grind where the hollowing of the blade starts away from the spine, partially down the blade, leaving a portion of the blade unground.

Common Use Cases: Since hollow grinds have more emphasis on precision and slicing than they do chopping or slashing, you’ll commonly see blades with a hollow grind being used in the kitchen.

Hollow grinds aren’t very common among EDC use but there are options available and while they certainly aren’t the most versatile blade grinds, they certainly would make a great companion if you know that your daily tasks mostly align with thin slicing, skinning, or shaving.

You won’t see hollow grinds on general-purpose camp knives or survival knives but you will see them on knives meant to be used for skinning game or cleaning fish. A lot of fillet knives may be available with hollow grinds.

Pros:

- Best in class slicing and maneuverability due to extreme sharpness and thinness of the cutting area

- Makes for excellent skinning knives or fish cleaners

- Can be strengthened with more material near the spine in the form of a partial hollow grind

- Easy to resharpen after a little practice as the edge is very thin

- Often used as an aesthetic type of grind since the blade looks sleek and thin

- Makes for excellent food prep blades due to its ease of slicing and ability to resist sticking more than most other grind types

- One of the least expensive grind styles to mass-produce

- An advantage in edge retention over most other grinds when being used on soft materials

Cons:

- Highly prone to failure when used as a heavy chopper, penetrator, or heavy cutting tasks

- The extremely thin edge is prone to rolling and chipping

- Can create a wedging effect when the shoulders of the spine contact the material being cut

- Poor choice for rigid materials making them difficult to recommend as an EDC or camping style grind

Marine Approved Example: Civivi Elementum

5. Scandinavian Grind (AKA Scandi) / Zero Grind

Description: A Scandinavian grind is going to consist of a single acute bevel, never more, that never encompasses an angle differential, meaning it will end at 0 degrees, hence the alternative naming scheme of zero grind. You can tell your knife has a Scandi grind when you see a nice unground portion of the blade, typically the majority of the blade, leading into a rather aggressive but even bevel.

Sometimes you might see variations of a Scandi grind but the truth is, if the angle from the bevel to the cutting edge changes at all, it’s a totally different grind type and not a Scandi grind. Some people may consider the V-grind to be the same as the Scandi grind but then again, most people agree that a Scandi grinds’ first and only bevel begins further away from the spine for additional thickness and strength over a traditional V-grind. I suppose you could say that some V-grinds are the same as Scandi grinds but not all, as a V-grind can also begin a lot closer to the spine on some knives than what a Scandi grind would begin at.

Scandi grinds have extremely thin edges which makes them especially sharp and easy to begin a cut with but have a lot of mass behind those edges making them exceptionally durable and overall rather strong.

These characteristics make the Scandi grind a favorite among people finding themselves out in the sticks but not able to carry with them multiple different knives. The Scandi grind doesn’t exactly lend itself to being the most precise or the strongest type of grind but more so focuses on being a rather decent all-rounder, with the exception of woodworking, it’s freaking great for that!

Common Use Cases: Scandi grinds are exceptionally useful in bushcraft and woodwork and as such, are almost always found on heavy outdoorsy related blades. If you’re looking for a solid camping knife, something to take backpacking with you, or perhaps something tough and reliable while hunting, a Scandi grind is likely to be among your best choices.

Pros:

- Exceptional initial cutting edge with a lot of strength and durability to boot

- Often a favorite among outdoorsman, especially in terms of survival or camping fixed blades

- Can be used on a myriad of tasks from chopping wood to food preparation

Cons:

- Sometimes a tough grind to resharpen as it requires removing quite a bit of material

- Scandi grinds can sometimes be a little too thin, especially after multiple resharpenings, on an otherwise abuse-oriented knife, making the edge easily damaged while the knife is supposed to be able to handle heavy tasks such as chopping or batoning

- Lacks performance in the slicing category

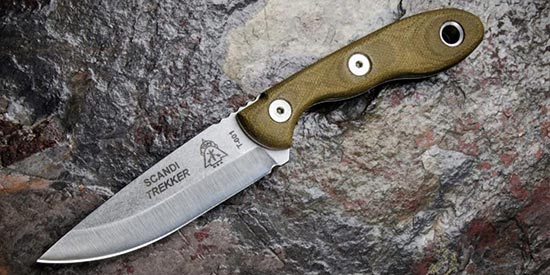

Marine Approved Example: Tops Knives Scandi Tracker

6. Chisel Grind

Description: A chisel grind is a type of asymmetrical grind that gives the blade a roughly 20 to 30 degree angle on one single side of the blade. As the name suggests, this type of grind is attempting to imitate that of an actual chisel tool, except in the form of a knife blade.

Many manufacturers and knife enthusiasts will argue, but at the end of the day, for the most part, chisel grinds provide an exceptionally strong and sharp edge on one side of the blade making them perform well in heavy-duty usage but require regular maintenance since the sharp edge is only on one side.

Sometimes a chisel grind can be combined with another type of grind. For example, a Sabre Chisel grind would encompass a secondary edge bevel, meaning there is a second bevel higher up on the blade from the cutting edge but still on the same side as the cutting edge. The other side of the blade is left flat.

If you’re new to the world of knives let me just tell you a little something about Benchmade. They love taking things that already have a name and, well, renaming them. If you come across something that says “opposing bevel” from Benchmade, like what’s on the Benchmade Triage 916, then just know that it’s likely just a regular asymmetrical chisel grind.

Common Use Cases: Chisel grinds are used in the same manner that a chisel tool would be used. They are great for making cuts away from you, chopping, or slashing at an angle.

Pros:

- Performs like a chisel tool

- The flat side typically aids in strength and durability making for a very strong blade

- Good for sharpened pry tools like the Ka-Bar Becker BK-3 Tac Tool

- Has less of a “suck-in” behavior when cutting meat, fish, thick fruits, and vegetables

- Easy to sharpen

- Good for scrapping tasks

Cons:

- Sometimes more difficult to use for someone new to knives

- Chisel ground knives do not make good EDC knives

- Keeping the chiseled edge sharp takes a lot more time and attention than other grinds

- Chiseled grinds can only be used in one direction, typically being used only by the same hand which can cause incompatibilities, especially for lefties!

- Difficult to make straight and even cuts

- Bad for woodwork or extremely precise cutting

Marine Approved Example: Emerson CQC-7

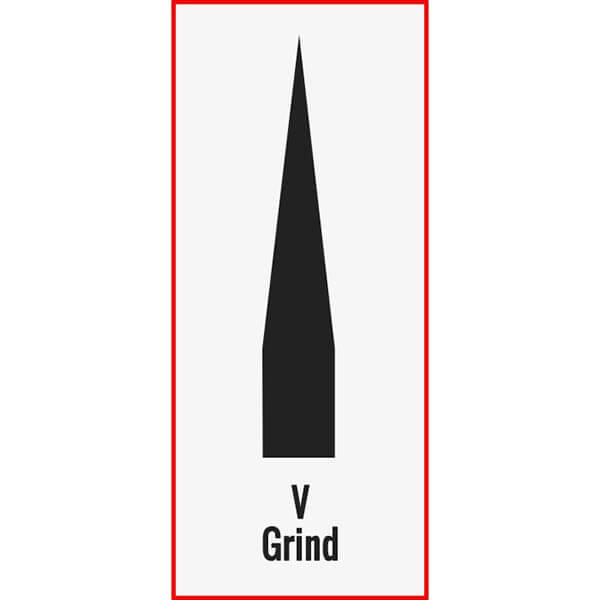

7. V-Grind

Description: Scandi grind was first so I’m assuming you already know that some V-grinds are basically the exact same thing as a Scandi grind, but not all of them! V-grinds are simply a version of a flat grind that has no angle change and only one single bevel. The main difference here between a V-grind and a Scandinavian grind is that the V-grind can start a lot higher, closer to the spine, than a traditional Scandi grind would ever even consider. The two are pretty much identical aside from the simple idea that V-grinds aren’t limited to the bottom portion of the blade nearest to the cutting edge.

Some would argue that a high V-grind is just a high flat grind and I suppose they would also be right. Naming grinds is kind of a mess to be totally honest with you and as I mentioned before we got into this rats nest, many of the terms are used loosely, modified by manufacturers, or simply interchangeable with one another.

Since some V-grinds start rather close to the spine, this means that they may have less material backing the blade’s durability, however, will improve their overall cutting and slicing performance over a regular Scandi grind. Of course, this only applies to a small amount of V-grinds as most manufacturers realize that the main advantage of these types of grinds is to beef them up near the spine and thin them out near the cutting edge.

V-grind is a term used a lot less often for the same things than say a high flat or Scandi grind but I wanted to give it its own category here because it can sometimes have subtle differences. I know, grinds can be confusing, and not having consistent attributes can be a little frustrating but at the end of the day, the difference between a V-grind, flat grind, and a Scandi grind are very little, and sometimes there is no difference at all.

Common Use Cases: Just like the Scandi grind, V-grinds are most often found in knives meant to be used heavily in the outdoors. These are the kinds of grinds you would want on the kind of knives you would trust your life with, such as survival knives, combat knives, tactical knives, camping knives, etc.

V-grinds make for excellent Bushcrafting knives which is why i’ll use the Morakniv Garberg or the Morakniv Bushcraft line as an example here. These are both a Scandi and a V grind at the same.

Pros:

- Allows the blade to be rather strong and durable by keeping a lot of the thickness of the blade near the spine but allowing the edge to be rather thin and sharp

- These types of grinds make for great versatility and outdoors knives

- Typically has similar or identical performance to a high flat grind with a little more thickness and strength at the spine

- Extremely popular and reliable among heavy-usage outdoor knives, like tactical or survival knives

- Better edge stability than grinds meant for slicing

Cons:

- Can sometimes lack purpose, being a general all-rounder but not particularly excelling in any one category

- Can be difficult to resharpen as there is a lot of material to be removed, especially after several resharpenings

- Generally heavier than most other grind styles (can be a pro)

- Usually has poor slicing performance

- Can cause wedging issues when needing to make deep cuts

Marine Approved Example: Morakniv Garberg (Technically both a Scandi and a V grind)

8. Compound Grind (AKA Complex Grind)

Description: Compound grinds are a relatively new and trendy style of blade finishing that encompasses two different grinds on the same blade. There is both an aesthetic reason and a utility reason behind this.

First off, aesthetically, a lot of high-end knife brands are simply using a compound grind to catch two different angles of light which makes them look super cool for Instagram or to put on their website for marketing purposes.

A lot of people think compound grinds are purely aesthetic, though, and although that may be the case in some instances where two grinds are chosen purely based on their appearance together instead of their performance together, compound grinds do have real-life advantages if done correctly.

The most pressing example for a utilitarian viewpoint on compound grinds is having a shallow hollow grind near the tip with a much thicker type of grind near the handle. This allows the knife to behave like an excellent slicer near the tip where you may use it to open letters, cut fruit, etc. The additional thickness near the handle allows for higher durability so in the chance your knife is deployed to be used on something less delicate but more troublesome, you have the thickness and durability to complete the job without damaging the portion of the blade that isn’t suitable for tough work.

As opposed to the aforementioned example, some knives, like one of our favorites, the Benchmade Vector 496, utilizes a much thicker style of grind near the tip to make for an insanely strong stabbing-capable blade but with the majority of the underbelly of the blade being a very shallow and thin type of grind so that most of the blade is capable of thin and precise slicing. The Vector is for those times when you need to prepare the veggies but also put that blade through the door of a car – all in a day’s work for some you, eh?

Common Use Cases: As mentioned before, a lot of knives come out beautifully when given a nice compound grind and many people are simply drawn to their more complex and aesthetic appeal so a common use case would simply be to create nice looking blades that sell for high premiums and look good on showcase.

A knife you take camping with you may see a wide variety of tasks all within the same day. Perhaps you use it to carve up some wooden stakes but then immediately find an apple tree and get to slicing some fresh lunch. A blade that has both a thin slicing edge and a thicker more durable edge gives you a lot of versatility, similarly to blades that use a partially serrated blade. Compound grinds on a blade is an attempt at making the knife an overall more useful and versatile tool, albeit sometimes it works like this and sometimes it doesn’t, it really depends on the two grinds being used and how they’re implemented by the knife manufacturer.

Pros:

- Offers a level of versatility not found in other grind styles

- Often provides a thin slicing cutting edge alongside a thicker and more durable cutting edge for harder tasks or stabbing/thrusting capability

- Many people including myself really appreciate the aesthetic appeal of a compound grind done right

Cons:

- Are generally more expensive than a blade that encompasses a single grind

- Can be a little tricky to properly maintain and resharpen

- May sometimes utilize two grinds that do not offer exceptional versatility

- The blade may simply not have enough cutting edge real-estate to make good use of two different grinds

Marine Approved Example: Benchmade Vector 496

9. Convex Grind (AKA Axe Grind)

Description: A convex grind sets the maximum amount of steel material throughout the blade all the way down to the cutting edge to enhance durability and focus on strength. You’re going to see these types of grinds on knives that are meant to be beaten and bruised like machetes and camp knives while it’s very rare to see this type of grind found on a pocket knife.

The shape of a convex grind looks a lot like your index finger with a gradual curve toward the tip coming to a rather blunt-like point. Convex grinds typically do not have especially sharp edges compared to something like a hollow grind but are more so great for high-pressure abusive use.

Convex grinds make for horrible slicing experiences and certainly aren’t made for any task that requires precision because they will take massive chunks out of whatever they touch but if you need to hack and slash your way through thick brush or put a lot of pressure on the blade from an angle other than directly above the spine like a pry bar (knives are not pry bars but things happen from time to time), the convex grind is what you’re going to want to opt for.

Hamaguri grind, Apple Seed grind, and Moran grind may also be terms you see, although seldom among pocket knives. These grind types are created with convex radiused bevels. Hamaguri is a technique using a convex grind to create a stronger, fuller tip for extra piercing capabilities. Hamaguri convex grinds are most commonly found on hatchets or swords where the idea is that the edge isn’t slicing but attempting to penetrate wood, armor, or other heavy materials.

Common Use Cases: Due to the increased strength and overall excellent durability of a convex grind, you’ll generally see this on outdoor specific knives, like survival knives or camping knives that may see chopping, splitting, and other heavy-duty usages where the blade may receive pressure from multiple angles.

A lot of swords, daggers, katanas, and even some tanto blades utilize some form of a convex grind since the additional weight and material aid in penetration against armor or thick clothing.

Pros:

- Convex grinds are typically found on your strongest and most durable blades

- Specifically used to be heavily abused in chopping, splitting, hacking, etc

- Make for great survival or camping knives due to their insane strength and ability to be used on basically anything with minimal edge damage

- Have the strongest edge of any grind style

- Easy to resharpen and maintain

Cons:

- Are awful for slicing due to their convex shape and thickness

- Typically makes the blade much heavier since there is more material on the blade than most other grinds

- Generally aren’t preferred for pocket knives or EDC knives

Marine Approved Example: Fallkniven A1

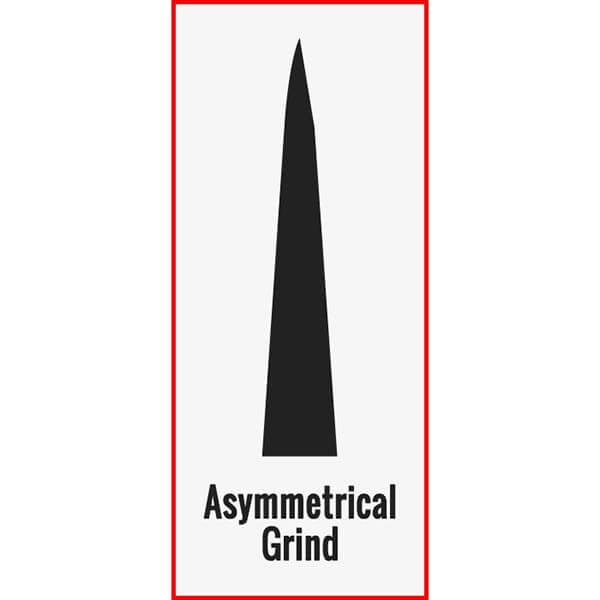

9. Asymmetrical Grind

Description: Asymmetry and asymmetrical can be used in a few different ways so it’s important to really know how the marketing material or the person you’re talking to is using it. On one hand, you might hear the term asymmetrical grind being used in tandem with another grind type, like a chisel grind. This is to signify that the grind is simply different on both sides of the blade instead of being the exact same on both sides, which would be called a symmetrical grind.

In many cases, high-end knife designers will use an asymmetrical grind to try and bring out the best of two different angles. This can be done for aesthetic reasons or to create an angle that is possibly stronger and more durable than had it not had a difference in angles.

In most marketing jargon, an asymmetrical grind is being referred to as a blade that simply encompasses two totally different grinds on each side of the blade, meaning that one side of the blade is going to look noticeably different than the other side.

In almost all cases where the grind is performed by hand, most grinds are going to be asymmetrical even if the idea was to be symmetrical in the first place because, well, grinding isn’t always an exact science and the differences between the two sides can be subtle but often exist nonetheless. Some people will use the term “asymmetrical grinds” as a complaint where the expectation was a perfectly symmetrical grind and the result of the finished product was not symmetrical.

I won’t make a special section for symmetrical grinds but just know that, if you see that, it just means the grind is the exact same or supposed to be the exact same, on each side. Most of the time you won’t come across any marketing material that says “symmetrical grind” as that doesn’t really offer the consumer a lot of information because a symmetrical grind could be a whole myriad of different styles.

I know this is a forum post but it does do a great job explaining how asymmetrical grinds work.

Common Use Cases: A big reason to have a knife designed to be asymmetrical can be derived from the kitchen. A kitchen knife may need to be relatively durable and robust, which would come from a big thick, and flat blade, but food sticks to a flatter grind so what we can do to get the best of both worlds is to make one side decently thick and flat and one side with a slight curvature. This helps the user steer the knife through food and have a lot less of the food sticking to the knife. This works because most people will hold the knife in the same hand every time they use it while they hold or somehow secure the food they are preparing with the other, meaning the knife operates at the same angle, the curved angle, thus giving the user the benefits of an asymmetrical grind.

Other use cases may simply come down to aesthetic appeal. Some of the high-end brands that make usable but expensive and aesthetically pleasing knives will sometimes opt for an asymmetric grind simply to make their blades stand out and look cool.

If you look closely, a lot of axes will have dramatically asymmetric grinds as well, since most people will be chopping wood in the same hand, thus using the same side of the ax. This has similar properties to a kitchen knife where the flat and thick side is to keep the durability of the ax head relatively high while the curved but slightly thinner side increases the axes actual chopping performance.

Pros:

- Offers extra durability while remaining somewhat slim and thin

- Can look aesthetically pleasing

- Can reduce material sticking to the blade, especially when dealing with food

Cons:

- Often more difficult to properly maintain and resharpen

- Can reduce cutting performance if used in an unintended angle

- Sometimes requires a little more experience and knowledge with knives to achieve the proper performance

Marine Approved Example: No example was given since this type of grind can come in many different configurations.

FAQs

The grind of a knife means it makes the blade thin and sharp so that it can cut through. Different types of grinds are used for different purposes.

Hollow grinds are the sharpest blade grind. They remain razor-sharp and thin rather than becoming thick, even after sharpening them.

Generally, most kitchen knives are convex grinds. They are long-lasting and easy to cut off since the pressure is pushed away from the angled edge.

Different knife edges are used for different purposes. Some popular knife edges are a flat grind, convex edge, compound bevel, hollow edge, chisel edge, and asymmetrical.

Very good information. One way of getting around the cons of a full flat knife is to do it on a thick AND LARGE blade. The width of the blade, if big enough, will give you a thick spine but still allow a thin edge. However, when chopping the wood can stick to the sides. If you want your knife to be able to deal with food prep as well, it could be a great camping knife. I know you know about this, I am just pointing out the importance of the width of the blade for a full flat.