This site contains affiliate links. As an Amazon Associate, I earn a commission from qualifying purchases at no extra cost to you. Full Disclosure Here.

If you’ve ever owned a knife before then I’m sure you’ve seen that little stamp on your blade with a string of letters and numbers. Those little numbers and letters are actually the primary driving force behind the price and performance you can expect out of that particular knife and, as with everything, not all knives and their blades are made the same!

How can you ensure you’re spending your hard-earned money and putting your trust into a quality knife? Well, you can start by reading this guide! We’ll help you find the best knife steel for the types of jobs you intend to use your knife for and make the decision easy with charts and explanations that even Marines can understand! Our team here at Marine Approved has lots of experience carrying and utilizing knives across countless situations. We have had to trust our blades with our lives so we know a thing or two about choosing a quality blade!

In this guide, we’ll first have a quick discussion about what different characteristics you should consider and how to choose between the plethora of available blade materials to best suit your situation and then we’ll review the most popular and highest performing steel types on the market thus far.

When reading through the different characteristics of steels, consider your own life and how you might carry and use your knife. Ask yourself questions such as:

- Do I use my knife to pry things?

- How often do I have time to service and care for my knife?

- Will I use my knife around saltwater?

- How important is overall sharpness to me versus how often I will need to sharpen the blade?

- Am I willing to sacrifice edge retention for blade hardness for edge longevity?

For those of you who want to learn more about what factors to consider before seeing the steel comparisons, I recommend reading this entire article. For those of you who want to jump straight to a particular section of this article, we put a quick navigation menu below. After learning about knife steels, consider checking out our favorite fixed blade knives here and EDC knives here.

A quick disclaimer here: New types and methods of manufacturing steel come about all the time and more often than not, a knife manufacturer may work with a company that specializes in steel to produce a product with specific characteristics. We won’t be able to cover each and every single steel ever used in the manufacturing process of knife blades but we will cover the most prominent and important steel types!

As with many of the products we use, review, and recommend, there are often stark contrasts between characteristics in performance and in almost all cases, there will be tradeoffs that only you can decide between. There are many different types of steel that can be used to make a blade but there are no types of steel that excel and dominate in every single category. There is no blade that does it all and does it all the best, but more so blades that may excel in something whereas they are giving up something else.

This is the reason that I believe anyone buying a new knife should be studying up on steel types to ensure their money is best spent on a knife that serves the purpose you specifically require! Of course, you get what you pay for and the top tier steel materials that you will pay an arm and a leg for will often excel in all categories over their cheaper counterparts.

Considerations When Choosing a Knife Steel

Blade Hardness and HRC Ratings

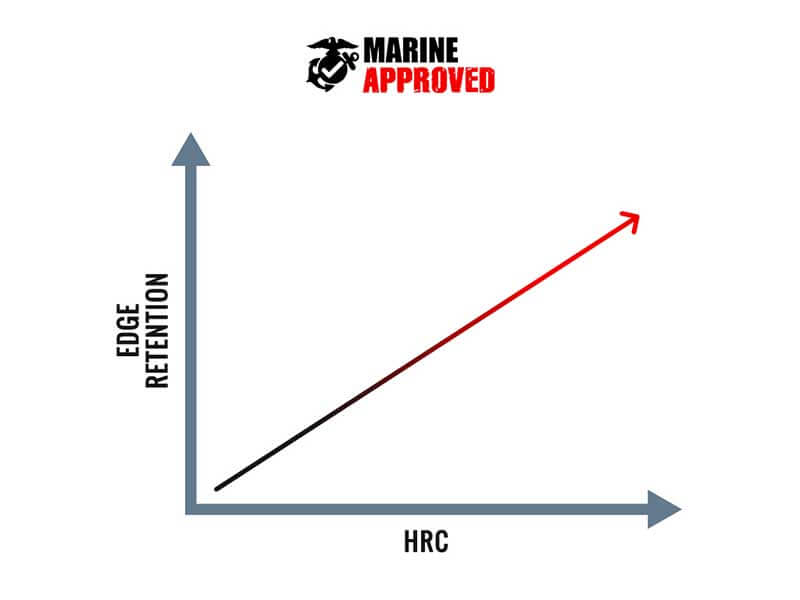

The hardness of a particular blade is often defined as its ability to resist rolling and caving in on itself. Generally, a harder steel material used to make a blade means that the blade will be stronger overall and resist damage to the edge and the overall blade.

The hardness level of steel is determined using a universal scale called the “Rockwell C Test”, commonly called the Rockwell hardness scale (HRC). Almost all consumer-grade pocket knives, EDC knives, fixed blade knives, etc will be in the range of a Rockwell Hardness rating of 54 to 65 HRC.

Most steel types themselves can be hardened or softened up a bit but the actual material composition of the steel usually dictates a specific range that steel performs well inside of. This means you can’t take a specific steel type and just harden it as much as possible or make it super flexible as it’s other properties may severely limit its ability to perform outside of its specified range.

What are the tradeoffs here?

The tradeoffs of an insanely hard blade are the ease of sharpening and overall flexibility. If a knife is ultra-hard, it will have little to no flex which can actually be counter-intuitive towards durability. Some flex in a blade may be a good thing and might help the knife to perform its intended duties without shattering. Perhaps you’ve seen bulletproof glass in action. The bulletproof glass actually flexes inwards a slight bit to help dissipate the energy of the bullet’s impact and thus makes the glass much stronger against shattering. Hard blades also create brittleness in the edge allowing for chipping and unevenness.

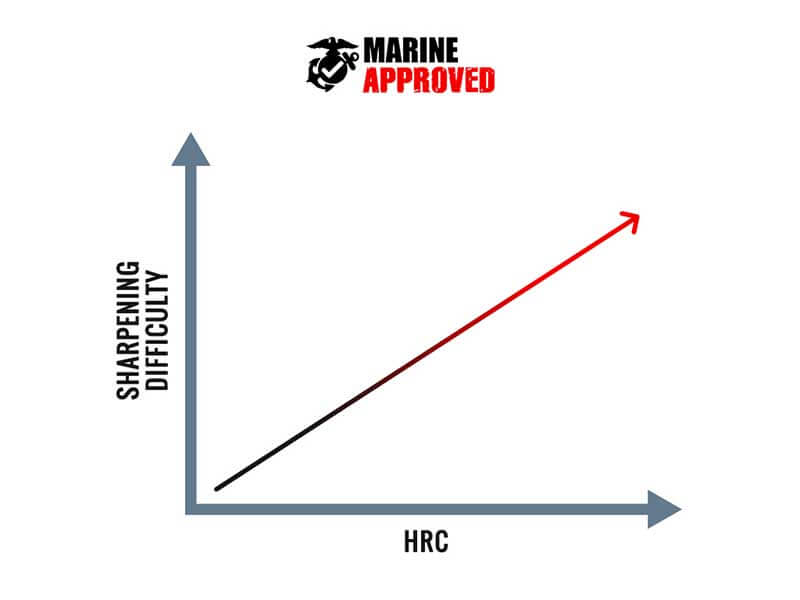

Hard blades are especially difficult to sharpen and may take longer periods of sharpening and special attention to achieve high-quality edges. On the flip side, a blade that is very soft will be easy to sharpen with little effort and time, however, will suffer edge loss even with light usage.

A blade whose hardness is in the middle of the regular blade range (Ex. 60) is likely the sweet spot for most people as they will be easily sharpenable but hard enough to survive regular abuse, however, choosing a blade with the perfect hardness may come at a cost in other characteristics, so choosing a blade strictly off its hardness rating is ill-advised but more so a single factor to consider among many.

If you’d like to study up on the Rockwell hardness scales intricacies and nuances, check out the AG Russell article on it found here. They have a pretty cool video on the test actually being performed so check that out as well!

Sharpening and Serviceability

As we mentioned above, the hardness of the material used to create the blade plays a huge factor in how the blade behaves when being sharpened. If you’re new to owning high-quality knives and you aren’t sure how to sharpen a blade properly and/or you don’t have hours on end to spend sharpening and maintaining a blade, you should be taking special consideration of the hardness level, which is defined above.

An especially hard type of steel, like one with an HRC rating of 64, may not take an edge from cheap and quick sharpening methods and may require a little investment of both time and money to maintain a sharp edge properly, so if you choose an especially hard type of steel, be ready to pony up some cash for a high-quality sharpener and exert a little elbow grease!

Furthermore, sharpening a blade is only part of the equation when it comes to caring for specific steel-based knives. Some knives may consist of materials that, when not protected, stain or rust easily. These may be protected with special types of oil that need to be applied every so often. Knives with moving parts, that is any type of hinge, folder, utility, or multi-tool, should be oiled to ensure the moving parts are easy to move and that the metal on metal contact isn’t causing excessive wear and tear. Some steel types, notably softer steels, may wear extremely quickly when not oiled properly.

A good example of a blade that should have oil applied to it often is steel mixed with high levels of carbon such as 420HC. Oiling the steel ensures water runs off of it and does not penetrate the pores in the steel, creating rust. Some knife steels, like VG-10, have carbon and steel mixtures but they also use chromium for corrosion resistance, so these would need far less and perhaps even no oil for longevity. As a rule of thumb, I’d give any blade of any steel composition a good mineral oil rubdown from time to time to be safe as technically, all steel based blades are prone to corrosion eventually.

Interested in a quick tutorial guide on how to sharpen your knife? Buck Knives has a very easy and thorough guide on knife sharpening that you can find here.

Edge Retention

Edge retention seems to be all the rage when talking about a blade. Some people may think edge retention is the most important characteristic because, let’s face it, if your knife doesn’t have a sharp edge when you need it, it’s a paperweight, not a knife. I’m sure you’ve heard the saying “A sharp knife is a safe knife and a dull knife is a dangerous knife”.

Edge retention is not a characteristic by itself. Edge retention is often reliant on other attributes such as blade hardness and steel composition. Often times, blades that have excellent edge retention are not blades that are exceptionally strong in overall tensile strength. If you need a blade that you can cut things with but also pry and wrangle within other methods, you might want to sacrifice some edge retaining ability for a steel that is notably strong and durable with some flex to it.

The major tradeoff with having an excellent edge retaining steel is brittleness in the overall blade. To get the best edge retention, you’d want an extremely hard steel composition but being too hard makes the blade brittle and prone to breaking and chipping. The best edge retention would render your knife useless in anything other than cutting soft materials as even the slightest flex could send part of your blade flying!

A last little tidbit here is that creating excellent resistance to corrosion will oftentimes sacrifice a bit in the category of edge retention. When adding chromium to steel or steel and carbon, the edge will become a little softer than what it would be as just steel. On the flip side, adding more carbon itself will increase the hardness and edge retention.

Most blades can be sharpened enough even when they have low levels of edge retention for the average user to be happy and enjoy decent performance throughout regular usage. Lower edge retention doesn’t mean the blade is bad for your specific use case as it may excel in things you really need, like resistance to saltwater as you use the knife on a fishing rig, just expect to sharpen more often!

If you’d like to learn more about edge retention and see some incredible data derived from direct testing, check out the findings in this article from The Knife Steel Nerds.

Corrosion Resistance

At this point, we’ve actually already hit on corrosion resistance a few times so you should have an idea of what I’m about to tell you. That’s right, a blade that is excellent in resisting corrosion will likely not be the strongest or have the best edge retention capabilities. That’s fine, though, especially if you really need corrosion resistance because hey, a knife that’s rusted isn’t going to do you much good.

If you live somewhere relatively dry and you don’t plan on using your knife in water or, even worse, saltwater, then corrosion resistance is one of the lowest tier characteristics you should be looking for and honestly, I wouldn’t worry about this much at all if that were the case. If it is the case, though, and you’re working on a boat or something like that, corrosion resistance is a must and is well worth trading off a little edge retention and strength to ensure your blade remains functional.

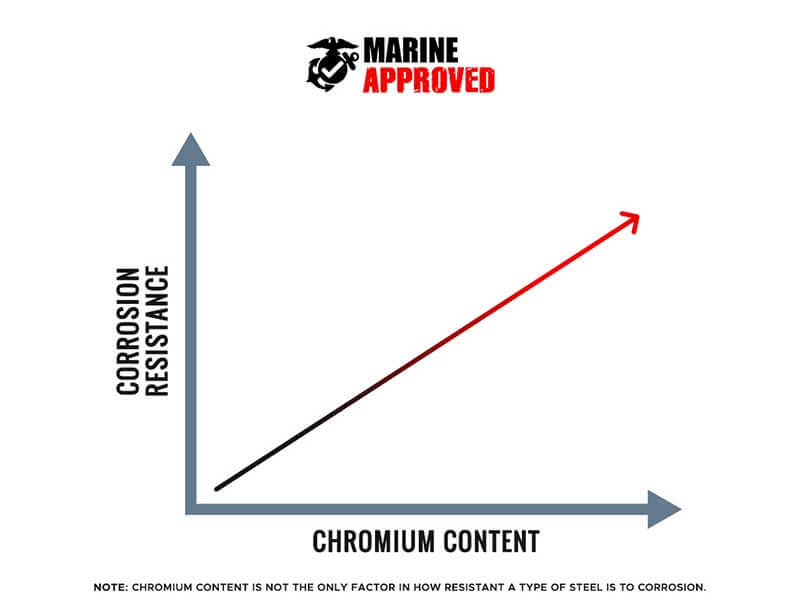

Corrosion resistance in the world of blade forging is almost always achieved now by adding chromium to the steel composition. Something like H1 steel has a high chromium content and thus is regarded as one of the best mid-grade corrosion-resistant steels. Stainless steel, or really just the “stainless” part, is referring to the addition of chromium in the composition of the steel.

Not all stainless is created equally and not all steel mixed with chromium will have a “stainless” tag with it upfront. Technically, to be considered a stainless steel composition, the steel mixture must contain a minimum of 10.5% of chromium, however, we know that much higher contents of chromium are necessary for resistance against especially corrosive environments such as usage in and near saltwater.

Chromium is not the only factor in how resistant a type of steel is to corrosion. How the steel is treated and what manufacturing process it undergoes will have a huge impact on corrosion resistance. For example, the heat and curing treatment steel undergoes will change the resistance to corrosion even with chromium mixed in, so not all stainless steel with the same chromium content will have the same level of resistance to rust.

Some examples of highly corrosion-resistant steel compositions are H1, LC 200 N, N690, and VG-10. Remember, even the best steels with respect to corrosion resistance can still corrode and still necessitates proper care, cleaning, and oiling to ensure they don’t rust away.

For those interested, the Knife Steel Nerds have a very interesting article about testing the corrosion resistance of different knife blade steels that you can read about here.

Grind

A blade’s ability to be ground will determine its behavior as it moves through whatever it is that you’re cutting. We aren’t super focused on the specific grind in this article, although this is an important attribute to study up on before buying a new knife.

Instead, we’re focused on how different steels react and are capable of being ground in specific styles. I won’t go too far in-depth, but keep in mind that special steels like H1, the especially corrosion resistance saltwater steel, cannot hold a flat grind due to a flat grind being too thin and brittle for H1 to hold an edge. An H1 steel blade with a full flat grind will have its edge virtually destroyed immediately, thus most H1 steel blades can only be found in grinds like a partial flat grind.

If a special grind style is a serious purchasing point for you, ensure the type of steel the blade is made of is capable of supporting that style and that you are ready for the required maintenance to keep it sharp and in good shape. Typically, really hard blades will have more grind choices while soft and corrosion-resistant steel may not be suitable for a lot of styles of grind.

You can learn more about knife blade grinds from the Marine Approved Knife Grinds page here.

Treatment

Compare two blades of the exact same steel composition and you’ll have two totally different blades, despite them consisting of the same materials. Why? Well, different manufacturers have different methods of how they treat their steel before and after it takes life as a blade.

We won’t go deep into the science here, but a big factor in how a specific steel will perform in a specific blade configuration comes down to how the steel is heat and/or cryogenically treated. It’s pretty difficult to tell how well a blade is treated until it’s well worn and compared to that of other similar steel compositions, so there’s no true method in determining whether a knife has been treated well or lackluster.

My advice here is to ensure your knife is coming from a reputable manufacturer and no, that doesn’t mean just the brand on the packaging but the actual manufacturer. Many brands might be manufactured in house if you’re looking at high-end blades, however, most low and mid-tier knives are manufactured by a parent company or outsourced to another company that may or may not treat their steel in the best manner.

So, what does differing steel treatment mean for you? Well, if you’re shopping around and you see something like a high-quality S90V blade being sold by a reputable brand and then also an S90V blade being sold by a budget brand, those knives will likely perform and degrade significantly different despite being labeled as the same high-quality steel. It doesn’t always benefit you to save some money and choose the cheaper blade as that blade’s steel composition may not be treated as well as the more expensive version.

This blade treatment guide from Sandvik has additional information and insight into the heat treatment process for those of you that are interested!

Here Are the Best Knife Steels (Ranked From Low to High Tier)

Low Tier Steels

Steel type: Unmarked Stainless steel and/or Surgical Steel (SAE 316, 440, 420, 17-4)

Common Use Case: Extremely cheap knives and disposable knives

| Steel Stats | Rating |

| Blade Hardness | Typically undefined |

| Sharpening Difficulty | Easy |

| Edge Retention | Undefined |

| Corrosion Resistance | Low and/or undefined |

| Toughness | Very low 1/10 |

Review: Knives that come stamped with unmarked “stainless steel” or “surgical steel” are often the cheapest possible materials and manufacturing processes and are never Marine Approved. You should stay away from these knives unless you plan on using them once and disposing of them as they are not of high quality and do not provide durability or peace of mind.

The real problem with surgical steel stamps is that there is little to no formal accountability for the results and attributes of surgical steel. In all reality, literally any steel blade that has even a hint of chromium for corrosion resistance can be dubbed surgical steel, even though to be considered actually corrosion resistant, it has to have over 10.5% of chromium content, which if that were the case, we’d be looking at a higher grade stamp instead of just this silly “surgical grade” or just “stainless steel” nonsense.

Steel type: 420, 420J, 420J2, and 420HC

Common Use Case: Budget American knives

| Steel Stats | Rating |

| Blade Hardness | 56-57 HRC |

| Sharpening Difficulty | Very easy 9/10 |

| Edge Retention | Bad 2/10 |

| Corrosion Resistance | Decent 4/10 |

| Toughness | Low 2/10 |

Review: Anything with a 420 stamped on it is probably of relatively low quality and on the budget end of the spectrum. That’s not to say these don’t have a place, as they are good starter knives and they’re easy to teach someone how to sharpen a blade with, but these are not knives I’d trust my life taking into the wilderness on a dangerous trek with.

420 steel is pretty basic steel with hardly any corrosion resistance on its own. I’d stay away from 420 base steel altogether. 420HC simply means it’s infused with a lot of carbon which makes the base 420 steel a bit harder and better overall than the regular 420 but unfortunately, it still suffers from similar drawbacks in toughness and wear resistance. 420HC does have decent resistance to corrosion but if you have a few bucks more to spend, you can get equally as resistant steels that are also better at holding an edge and are generally more reliable.

420HC from Buck Knives is generally of higher quality than 420 or 420HC. Buck Knives delivers fantastic quality 420HC with a special treatment that hardens the 420HC over the regular 57HRC we’d expect and significantly improve upon the durability and edge retention. If you’re on a very tight budget but you need something of decent quality, a Buck Knife with 420HC is simply okay.

420J and 420J2 are the middle ground between 420 stainless and 420HC. While 420 has very little carbon and 420HC is high carbon-based, 420J has a medium carbon content, giving it medium performance in an already extremely low tier steel composition.

One of the Marine Approved top recommendations for a knife encompassing this material is the Buck Knives Ranger 112.

Steel type: AUS-6

Common Use Case: Budget Japanese/Chinese knives

| Steel Stats | Rating |

| Blade Hardness | 55-57HRC |

| Sharpening Difficulty | Very easy 9/10 |

| Edge Retention | Bad 2/10 |

| Corrosion Resistance | Medium 5/10 |

| Toughness | Low 2/10 |

My Review: AUS-6 is essentially the Japanese version of the 420HC high carbon steel with the same relatively soft average hardness rating of 57. Being soft makes these blades very easy to sharpen and that’s great because you’ll be sharpening them often to keep an edge, almost desperately at that. In Marine Approved fashion, we suggest opting for higher quality as AUS-6 is typically found on low-end budget knives that maybe you’d buy as a first-time knife gift for a youngster or something in that nature. SOG makes some okay AUS-6 knives but other than that, no notable brands I’d really recommend carries AUS-6 blades.

AUS-6 steel is rarely used to build pocket knives or fixed blade knives and is typically found in kitchen knives nowadays.

Steel type: 440A / 13C26

Common Use Case: Being of higher quality than 420 but still used in budget blades

| Steel Stats | Rating |

| Blade Hardness | 55-58 HRC |

| Sharpening Difficulty | Very easy 9/10 |

| Edge Retention | Bad 3/10 |

| Corrosion Resistance | Bad 2/10 |

| Toughness | Very low 1/10 |

Review: 440A is essentially just that good ol’ 420HC with but with even more carbon. More carbon sounds like a good thing, I mean it’s more expensive, right? Well, it is more expensive and it is better in some areas but there are glaring tradeoffs that cannot be ignored.

The higher level of carbon found in 440A makes the blade significantly stronger and more wear-resistant than the 420HC blades, however, this makes them prone to corrosion much more than 420HC so it’s a type of tradeoff that, if you’re in the market for a low-quality budget blade, you’ll have to decide upon yourself considering the situations in which you’ll use your knife.

13C26 is essentially a special version of 440A that simply has higher levels of carbon in place of chromium and as such, sacrifices a little corrosion resistance for strength, however, the difference is very small and the two are almost identical in practical use.

One of the Marine Approved top recommendations for a knife encompassing 440A steel is the Gerber Hinderer.

Steel type: 1095 Carbon

Common Use Case: Extremely popular inexpensive steel that tends to outperform other steels in this tier.

| Steel Stats | Rating |

| Blade Hardness | 55-56 HRC |

| Sharpening Difficulty | Very easy 9/10 |

| Edge Retention | Decent 4/10 |

| Corrosion Resistance | Bad 2/10 |

| Toughness | Medium 5/10 |

Review: 1095 carbon steel is one of the most popular steel compositions found in knives pretty much everywhere. These are low-cost inexpensive blades whose properties generally exceed other low-cost materials but still don’t quite stack up to what would be considered a decent knife.

Don’t get me wrong, 1095 is good for a starter blade or something you don’t use or rely on often but these are not blades I’d rely on to save my life unless I had no other higher-quality choice, which isn’t the case, so 1095 blades are a hard pass for me personally.

1095 is well known for its tensile durability in the low-cost market. These blades have a much higher resistance to chipping and breaking than the other low tier materials but fall short when it comes to corrosion resistance as they are essentially pure steel with roughly 1% carbon and virtually no chromium to resist rust. These are some of the easiest blades to sharpen, though, so like I said, they’re good as a starter blade material.

One of the Marine Approved top recommendations for a knife encompassing 1095 steel is the ESEE Knives Izula II.

Mid Tier Steels

Steel type: AUS-8, AUS-10A, 8Cr13MoV, and 440B

Common Use Case: Wide variety, usually in low to mid-range multi-purpose knives

| Steel Stats | Rating |

| Blade Hardness | 58-60 HRC |

| Sharpening Difficulty | Very easy 9/10 |

| Edge Retention | Bad 2/10 |

| Corrosion Resistance | Low 3/10 |

| Toughness | Decent 4/10 |

Review: AUS-8 is the Japanese version while 8Cr13MoV (MoV) is the Chinese version and although they’re from two different places, they are relatively the same and behave almost identically. There is a little difference, though, and that is that AUS-8 has a tad bit more carbon mixed in, making it the harder and more durable option but not as good at resisting corrosion as the Chinese equivalent.

Benchmade makes a few knives with AUS-8 steel, does that sum this up? No, it doesn’t, because those are Benchmades lowest tier knives and nowhere near the performance of higher-grade steels but it is something to say for AUS-8 and is pretty cool they’re being used with a premium brand. The reason it’s used there is for its low cost of manufacturing to a relatively high level of durability compared to the cheaper solutions. Both of these steels have incredible value and are also extremely available and easy to buy in bulk.

AUS-10A is relatively new and simply trades in a very small amount of corrosion resistance for overall toughness since it swaps out some of the chromium used in AUS-8 with vanadium. The difference is real but you would be hard pressed to tell the difference between the two in person.

440B is often compared to AUS-8 as it has similar properties but is not quite as durable or popular as AUS-8. 440B steel is not a very popular material for the top knife brands due to having relatively the same price as 440C but without as good as edge retention.

I must also note that companies like Benchmade and Spyderco have much higher quality heat treatment processes for these types of steels than most other companies and as I mentioned in the guide, their blades will perform significantly higher than other brands with the same stamps so please keep that in mind. Not all AUS-8 or MoV steel blades are the same and some of them are relatively cheap, meaning they’re also fairly low quality in most cases.

One of the Marine Approved top recommendations for a knife encompassing AUS-8 steel is the 5.11 Tactical CS1.

One of the Marine Approved top recommendations for a knife encompassing AUS-10A steel is the Cold Steel Counter Point 1.

One of the Marine Approved top recommendations for a knife encompassing 8Cr13MoV steel is the CRKT M21-04G.

Steel type: CTS-BD1 (Spyderco Special Request)

Common Use Case: Many Spyderco Knives

| Steel Stats | Rating |

| Blade Hardness | 58-60 HRC |

| Sharpening Difficulty | Fairly easy 6/10 |

| Edge Retention | Decent 4/10 |

| Corrosion Resistance | Medium 5/10 |

| Toughness | Medium 5/10 |

Review: CTS-BD1 was requested by a special request from Spyderco to the US company Carpenter. In a nutshell, they took the properties of AUS-8, added a tad bit of chromium to increase its corrosion resistance, and then heat-treated it inside a vacuum to achieve larger chromium carbide particles that aid in resistance to corrosion better than something else with similar chromium levels but not vacuum treated.

Blades constructed of CTS-BD1 encompass great value for the price you pay since they are decently well-rounded and perform better in terms of resistance to rust than AUS-8 and MoV. This is why many people including our Marines here consider Spyderco to be of great value. They are priced competitively against similar steel compositions but provide a slight edge over their competitors with superior heat treatment.

When this steel first hit the market, Spyderco was the only company using it, however, many other reputable knife companies started to use it such as Cold Steel.

One of the Marine Approved top recommendations for a knife encompassing CTS-BD1 steel is the Spyderco Manix 2.

Steel type: Swedish Sandvik 12C27 / 13C26 / 14C28N (Kershaw special request but not exclusive)

Common Use Case: Many Kershaw knives but also other inexpensive knives like Morakniv

| Steel Stats | Rating |

| Blade Hardness | 55-62 HRC |

| Sharpening Difficulty | Fairly easy 7/10 |

| Edge Retention | Low 3/10 |

| Corrosion Resistance | Medium 5/10 |

| Toughness | Medium 5/10 |

Review: The Sandvik 12C27 fine grain steel has been around for a very long time and used to be an extremely popular material to craft blades from because it was often seen as a very well-rounded and inexpensive material to get decent performance from in the mid-tier. Many razor blades consist of this steel today and you can still find excellent knives consisting of this steel at ridiculously good prices.

13C26 is an excellent choice for razor blades but not so much used for pocket knives or fixed blades due to its lack of edge retention. These blades can be extremely sharp but unfortunately, they just require far too much sharpening to be worth the hassle.

Kershaw wasn’t exactly thrilled about the old 12C27 or 13C26 so they waltz right over to Sandvik and asked them to cut out some carbon and make way for a little chromium and nitrogen. The result is the same steel with better corrosion resistance. 14C28N is arguably one of the top budget options for medium well-rounded performing blades.

Although the reduction in carbon made them lose a little edge retention, this steel is super easy to sharpen and can be sharpened to a much higher level than other steel grades in similar price ranges.

One of the Marine Approved top recommendations for a knife encompassing 12C27 steel is the Morakniv Bushcraft.

One of the Marine Approved top recommendations for a knife encompassing 14C28N steel is the Kershaw Blur.

Steel type: 440C US Based

Common Use Case: This used to be a top contender but now is used as a general use mid-tier material

| Steel Stats | Rating |

| Blade Hardness | 59-60 HRC |

| Sharpening Difficulty | Fairly easy 7/10 |

| Edge Retention | Low 3/10 |

| Corrosion Resistance | Medium 5/10 |

| Toughness | 6/10 |

Review: 440C used to be the cool kid on the block and was regarded as such for a very long time, appearing in some of the best knives of that time period. That time period has now come and gone and 440C has been reduced to a med-grade steel composition that is still widely used by a lot of US knife companies to create general-use well-rounded blades.

440C is one of the better edge holders of the 400 steel series but still lacks in this department when compared to higher quality steel. 440C has a much higher composition of chromium and carbon than the lower tier 420HC giving it the edge when it comes to edge retention and corrosion resistance.

One of the Marine Approved top recommendations for a knife encompassing 440C steel is the Boker Magnum Shadow.

High Tier Steels

Steel type: American 1080 / Japanese SK-5

Common Use Case: Mid-priced extra hard blades

| Steel Stats | Rating |

| Blade Hardness | 62-65 HRC |

| Sharpening Difficulty | Very hard 2/10 |

| Edge Retention | Excellent 8/10 |

| Corrosion Resistance | Low 3/10 |

| Toughness | Good 6/10 |

My Review: These metals aren’t used as much as many of the others on this list but one brand that we really enjoy at Marine Approved in the medium tier level of knives is CRKT. They seem to have done an excellent job turning this ultra-hard but very brittle material into an extremely tough and durable blade with the use of special heat treatments and very high carbon contents.

These blades have above average hardness and edge retention compared to blades of similar price points and tiers but are very difficult for a beginner to sharpen and can prove to be lower in resistance against corrosion since most of the composition is carbon but lacks a whole lot of chromium.

One of the Marine Approved top recommendations for a knife encompassing SK-5 Steel is the CRKT Clever Girl.

Steel type: D2

Common Use Case: Mid-priced enthusiast style blades

| Steel Stats | Rating |

| Blade Hardness | 55-62 HRC |

| Sharpening Difficulty | Hard 3/10 |

| Edge Retention | Very good 8/10 |

| Corrosion Resistance | Low 2/10 |

| Toughness | Good 6/10 |

Review: D2 is the steel you buy if you really enjoy the finer details and time-consuming nature of blade sharpening. D2 steel doesn’t exactly stand out in the positive side of attributes but many choose D2 for its low price but relatively high toughness and hardness. D2 isn’t stainless steel because it falls short of the chromium requirement at just 13%. A low level of chromium means D2 doesn’t do well with corrosion whatsoever but so long as you keep it dry and clean, it should be alright.

D2 is infamous for how difficult it is to sharpen. With an HRC rating of up to 62 and a lack of softer materials in its composition, many believe D2 is one of the hardest blade materials to sharpen and is not suitable for beginners. It would seem as though you could get better properties overall with the same hardness in other steels such as 154CM so, if possible, I’d opt for something else on the super-hard spectrum if possible, but D2 is still pretty good and widely used today to create mid-grade blades.

One of the Marine Approved top recommendations for a knife encompassing this material is the Benchmade Adamas.

Steel type: A2

Common Use Case: Fixed blade combat and tactical applications

| Steel Stats | Rating |

| Blade Hardness | 57-62 HRC |

| Sharpening Difficulty | Hard 3/10 |

| Edge Retention | Good 7/10 |

| Corrosion Resistance | Very low 1/10 |

| Toughness | Very good 7/10 |

Review: A2 isn’t very common for something like an EDC pocket knife but it is common for when you need something insanely tough and durable to drag with you through combat. Blades consisting of this steel usually don’t last very long in terms of overall longevity but they can endure massive amounts of abuse without snapping or shattering. A big contributor as to why these don’t last long is the less than 5% chromium content rendering them open prey to rust and degradation.

One of the Marine Approved top recommendations for a knife encompassing A2 steel is the Bark River Gunny Hunter.

Steel type: H1

Common Use Case: Top anti-corrosion performance

| Steel Stats | Rating |

| Blade Hardness | 57-59 HRC |

| Sharpening Difficulty | Very easy 9/10 |

| Edge Retention | Very low 1/10 |

| Corrosion Resistance | Maximum performance 10/10 |

| Toughness | Medium 5/10 |

Review: H1 steel is derived from the Japanese Myodo Metals and is the Yang to the D2’s Yin. While D2 steel focuses on being super hard and tough, the H1 took a softer approach to combat the same corrosion that is the D2 Achilles Heel. Basically, H1 steel is a soft metal with a bunch of material mixed in that’s anti-corrosive and thus, H1 is one of the top performers when it comes to corrosion resistance, however, H1 lacks massively in many other categories such as sharpness, hardness, and edge retention since it has very low carbon.

Want to learn why H1 steel has such incredible resistance to corrosion? The Knife Steel Nerds have an insanely in-depth article about how H1 steel has achieved its corrosion resistance reputation.

One of the Marine Approved top recommendations for a knife encompassing H1 steel is the Spyderco Ladybug 3.

Steel type: 154CM / ATS-34

Common Use Case: Entry level to premium grade blades

| Steel Stats | Rating |

| Blade Hardness | 58-61 HRC |

| Sharpening Difficulty | Medium 5/10 |

| Edge Retention | Good 7/10 |

| Corrosion Resistance | Decent 4/10 |

| Toughness | Good 7/10 |

Review: 154CM is considered the upgraded version of 440C and it’s upgraded by adding molybdenum in place of some of the chromium 440C has. This elemental swap provides 154CM a far better edge retention than 440C and many of the steels used in blades today while sacrificing pretty much nothing in terms of corrosion resistance from the original 440C. Sounds too good to be true? Well, knives consisting of this material are going to be very costly and that’s probably why you see this material used across premium brands like Benchmade often.

ATS-34 is the Japanese equivalent to the US-made 154CM and pretty much sums up the same excellent properties found there with a slight but almost unnoticeable reduction in corrosion resistance. Both are excellent steel materials but I’d opt for the 154CM if given the choice.

One of the Marine Approved top recommendations for a knife encompassing 154CM steel is the Benchmade Nimravus.

Steel type: LC200N AKA Z-Finit

Common Use Case: Excellent middle ground between H1 steel and 154CM steel

| Steel Stats | Rating |

| Blade Hardness | 59-60 HRC |

| Sharpening Difficulty | Medium 5/10 |

| Edge Retention | Good 6/10 |

| Corrosion Resistance | Good 7/10 |

| Toughness | Good 7/10 |

Review: LC200N was originally an aerospace material used primarily to create ball bearings and was designed by the European company ZAPP. Of course, the same attributes that make for excellent aerospace grade steel usually line up decently well for attributes in the knife world and in this case, LC200N sits perfectly between that of H1 and 154CM. Now, you might be saying “but H1 and 154CM are totally different and have totally different pros and cons” and you’d be right. I’ve been telling you that you always have to trade something off for excellence in one category or another and I suppose that doesn’t ring so true here, at least not anymore.

LC200N really bridges the gap between the hardness and toughness 154CM brings to the table and the excellent corrosion resistance offered by H1. You can think of LC200N as being very similar to 154CM but with some of its carbon being traded out for nitrogen, allowing for the steal to still come in at incredible hardness levels but giving the steel a massive advantage in corrosion resistance over 154CM.

One of the Marine Approved top recommendations for a knife encompassing LC200N is the Spyderco Spydiechef.

Steel type: VG-10 / N690

Common Use Case: When you want the quality of 154CM steel but need a little more corrosion resistance

| Steel Stats | Rating |

| Blade Hardness | 59-61 HRC |

| Sharpening Difficulty | Medium 5/10 |

| Edge Retention | Good 7/10 |

| Corrosion Resistance | Very good 8/10 |

| Toughness | Good 7/10 |

Review: VG-10 steel is quickly becoming a top choice for premium blade slinging companies and for good reason, it’s capable of being sharpened ultra-sharp, it has incredible overall strength and durability, and it’s got better corrosion resistance than 154CM and ATS-34 in relatively the same price range.

VG-10 is basically 154CM with a tad bit more chromium and some fancy vanadium, which increased its corrosion resistance and toughness over 154CM respectively. It’s quite common to find knives that are multi-use and abuse-friendly consisting of VG-10 in the mid to high price spectrum and many of these really pound down the corrosion resistance of VG-10 in their marketing, and rightfully so, this is one of the toughest metals used in blades that maintain such fantastic resistance to the elements.

VG-10 is also well known and well-loved in the food industry as VG-10 cutlery has a reputation of surviving with a sharp edge throughout long and busy shifts.

Bohler N690 is widely known as VG-10 on steroids, simply having extremely similar performance and characteristics but encompassing slightly better edge retention and being a tad bit more difficult to sharpen when need be. It achieves these very slight advantages by being finer grain steel, but seriously, the two together in the wild are nearly indistinguishable.

One of the Marine Approved top recommendations for a knife encompassing VG-10 steel is the Boker Plus Urban Trapper.

One of the Marine Approved top recommendations for a knife encompassing N690 steel is the Spyderco Urban Leaf.

Premium Tier Steels

Steel type: Cheaper CPM Family (M4, S35VN, and S30V)

Common Use Case: High-end cutlery and knives

| Steel Stats | Rating |

| Blade Hardness | 60-66 HRC |

| Sharpening Difficulty | Hard 3/10 |

| Edge Retention | Very good 8/10 |

| Corrosion Resistance | 7/10 Except for M4 which is 3/10 at best |

| Toughness | 9/10 |

Review: CPM stands for Crucible Particle Metallurgy process and signifies a special process in which starts off similar to regular processes in that they give the steel a good old fashioned bath in molten steel but instead of being cast into molds, a high-pressure jet with that bursts the molten steel into tiny droplets than then dry into a powder in an atomization tower. This powder is then screened and then pressurized to form a particulate bond that creates a microstructure whose properties are extremely fine and homogenous. This eliminates segregation among each particle resulting in every single particle consisting of the exact same particulate matter.

Long story short, CPM stuff is much stronger than non-CPM stuff because it’s blasted into particles that are fine and evenly consisting of all the goodies we want in our blade. This applies to all of the CPM metals on this list.

For more information on the Crucible Particle Metallurgy process, check out the Crucible info page.

CPM steels used in the creation of our favorite blades render some of the highest quality and overall most satisfying blades. These were designed in the US with the utmost highest performance in mind for cutlery and pocket knives and when compared with other steel on a cost versus performance basis, CPM steel almost always wins by a fair margin.

Why is CPM so good? Well, aside from M4, which we’ll talk about later, CPM is exceptionally resistant to corrosion as its anti-corrosive properties are perfectly situated throughout the blade in each and every particle. S30V and S35VN are both exceptionally easy to maintain and sharpen and they hold an edge exceptionally well too, something you don’t normally get both of.

CPM M4 is a little different. Molybdenum is added with vanadium and tungsten and a ton of carbon to create a knife with a hardness level that exceeds S30V and S35VN, coming in at up to 65HRC. To achieve such hardness, a lot of the chromium was replaced with the aforementioned matter and thus no longer meets the requirement to be considered stainless steel. The tradeoff of all this wonderful hardness is a lack of resistance to corrosion.

One of the Marine Approved top recommendations for a knife encompassing CPM-M4 steel is the Benchmade Contigo 810.

One of the Marine Approved top recommendations for a knife encompassing CPM-S30V steel is the Benchmade Turret 980.

One of the Marine Approved top recommendations for a knife encompassing CPM-S35VN steel is the Off-Grid Knives Scorpion Elite.

Steel type: CTS-XHP

Common Use Case: High-quality especially hard and dense blades

| Steel Stats | Rating |

| Blade Hardness | 59-62 HRC |

| Sharpening Difficulty | Very difficult 2/10 |

| Edge Retention | Excellent 9/10 |

| Corrosion Resistance | Medium 5/10 |

| Toughness | Excellent 7/10 |

Review: This is yet another powder metallurgy process similar but slightly different to the CPM method. CTS-XHP actually exceeds the early S30V in edge retention, however, that edge is brittle and delicate and must be used with care. Basically, what you’re getting here is upgraded D2 steel where you get an insanely hard blade with very little flex that is incredibly difficult to sharpen but holds that sharp edge for an incredible length of time. They certainly weren’t looking for well-rounded but more so for a razor-sharp edge that stays razor-sharp for a very long time.

One of the Marine Approved top recommendations for a knife encompassing CTS-XHP steel is the Cold Steel Recon 1.

Cutting Edge Enthusiast Grade Steels

Steel type: More expensive CPM Family (20CV, S90V, and CPM S110V)

Common Use Case: The ultimate all-around tough and sharp blade

| Steel Stats | Rating |

| Blade Hardness | 58-66 HRC |

| Sharpening Difficulty | Extremely difficult 1/10 |

| Edge Retention | Exceptional 10/10 |

| Corrosion Resistance | Medium 5/10 |

| Toughness | Very good 7/10 |

Review: All of the same stuff we talked about earlier in the cheaper CPM family section applies here except these are better. Better in what way, you might ask? Well, let’s break them down individually.

CPM 20CV is a similar version to the M390 steel and CTS-204P but with better edge retention and wear resistance. 20CV was purpose-built to be a tank-like blade and a tank-like blade is exactly what you get here. CPM 20CV is the more corrosion resistant version of the high tier CPM family.

CPM S90V sacrifices a little of the 20CV corrosion resistance for an even harder blade consisting of much less chromium and a whole lot more vanadium. Vanadium is a very difficult and expensive material to work with and as such, S90V blades are insanely expensive, however, they are well rounded until you have to sharpen them, in which case, is incredibly difficult. S90V is the king of edge holding, though, so despite the fact its time consuming and frustrating to get that perfect edge, once you do, it’ll hang around for a while.

CPM S110V is simply the all-out full-throttle steel used to create some of the toughest and longest-lasting blades the world has ever seen in the consumer market. It’s incredibly hard for a manufacturer to get it right and even harder to prime up the edge, but once done correctly, this knife is staying exactly as it is for a ton of time and loads of abuse. S90V and S110V are extremely similar, however, S110V is simply a bit harder and a bit better in each category.

One of the Marine Approved top recommendations for a knife encompassing CPM-20CV steel is the Cold Steel Recon 1.

One of the Marine Approved top recommendations for a knife encompassing CPM-S90V steel is the Benchmade Nakamura Axis 484-1.

One of the Marine Approved top recommendations for a knife encompassing CPM-S110V steel is the Spyderco Military.

Steel type: M390

Common Use Case: Extremely high-quality knives that face both environmental and user abuse daily

| Steel Stats | Rating |

| Blade Hardness | 60-62 HRC |

| Sharpening Difficulty | Very difficult 2/10 |

| Edge Retention | Excellent 9/10 |

| Corrosion Resistance | Very good 7/10 |

| Toughness | Very good 7/10 |

Review: M390 was created by Bohler-Uddeholm and is a powder metallurgy tool steel similar to the CPM style steels. With a whole lot of chromium and an insanely hard blade, these are excellent all-around blades meant to withstand both nature and you with the obvious tradeoff of being insanely hard to sharpen and manufacture. Bohler uses vanadium and molybdenum carbides to stabilize the steel so that the chromium can do its job most effectively and block any rust from forming up.

A little fun fact about M390, this steel is often dubbed the “MicroClean” steel as it can be polished and cleaned up to resemble a mirrored surface. These blades are as beautifully dazzling as they are rough and tough! Good luck sharpening them!

You can read more about this from Bohler’s article on M390 steel here.

One of the Marine Approved top recommendations for a knife encompassing M390 steel is the Benchmade Barrage 581.

Steel type: ZDP-189

Common Use Case: Extremely hard blades

| Steel Stats | Rating |

| Blade Hardness | 64-66 HRC |

| Sharpening Difficulty | Among the most difficult 1/10 |

| Edge Retention | Excellent 9/10 |

| Corrosion Resistance | ood 6/10 |

| Toughness | Very good 7/10 |

Review: ZDP-189 is designed and created by Hitachi for the sole purpose of being insanely hard, both in physical hardness and sharpening. Okay, fine, they didn’t design it to be hard to sharpen but it certainly feels that way if you give it a go. The first part was true, though, and with a ton of carbon and chromium, 66HRC is achieved alongside a very reputable level of corrosion resistance. The only thing holding them back is the fact that using a ton of carbon offsets the chromium and brings the level of corrosion resistance down to a normal level. It’s not bad, it’s just not superb.

Basically, you would use ZDP-189 in place of S30V if you need a bit more hardness, and resistance to corrosion isn’t that important to you.

One of the Marine Approved top recommendations for a knife encompassing ZDP-189 steel is the Spyderco Dragonfly 2.

Steel type: Elmax

Common Use Case: To create a profile of well balanced high-quality attributes

| Steel Stats | Rating |

| Blade Hardness | 57-62 HRC |

| Sharpening Difficulty | Rather difficult 3/10 |

| Edge Retention | Excellent 9/10 |

| Corrosion Resistance | Medium 5/10 |

| Toughness | Very good 7/10 |

Review: Elmax is probably the most well rounded top tier steel you can find today and this beauty of blade steel was manufactured and designed by Uddehom before the buddied up in a merger with Bohler (Now Bohler-Uddeholm). This is another powder metallurgy process that uses a bunch of expensive and hard to work with goodies like vanadium, chromium, and molybdenum alloys and smacks them all together, forming what feels and acts like carbon-based steel without the carbon-based steel negatives. Knives of this material are surely going to cost a pretty penny but they will also likely live longer than you and they won’t shave off years of your life for sharpening, either!

One of the Marine Approved top recommendations for a knife encompassing Elmax steel is the Spyderco Lil Lion Spy.

Other Types of Blade Materials

Titanium: Despite titanium being insanely strong and super lightweight, you won’t find too many knives consisting of the material. While titanium makes for a fantastic blade structure, it fails to hold an edge. You may find custom knives meant to look pretty or some specialty knives such as dive knives made out of titanium but you certainly wouldn’t want one as an EDC.

Damascus: This is actually a method of creating steel that dates back to the ancient European crusades. Of course, the methods to create Damascus have changed since then and nowadays, Damascus is used in creating collectors knives as it produces brilliant weld patterns and alluring blade aesthetics. Damascus is done by hand, pattern welding several layers of different types of steels over one another as they are folded about each other. In high-quality Damascus blades, you’ll still find plenty of performance and durability, but I would think you could just spend much less on something else if those are properties important to you.

One of the Marine Approved top recommendations for a knife encompassing Damascus steel is the Benchmade Foray 698-181 Gold Class.

Ceramic: These aren’t your typical EDC blades as they are far too brittle but they do make amazing purpose-built applications such as use for dive knives and knives aboard fishing vessels. Ceramic knives absolutely cannot rust and thus have superior corrosion resistance to pretty much everything on this list. Ceramic blades are pretty much impossible to sharpen yourself but typically come with ultra razor-sharp edges that hold for a decent period of time. You can learn more about ceramic knives here.

Most Common Ingredients Used to Create Steel Blades

Carbon: One of the base ingredients making up steel is carbon, typically consisting of one of the majority shareholders in the composition of the blade. You can’t have steel without carbon as it is the most crucial hardening element. With that said, adding too much carbon can make the steel so hard that it actually becomes brittle and has little to no flex capabilities. When shopping around, taking note of the amount of carbon in the steel used for the blade is very important. For example, a blade labeled as low carbon means it has less than .3%, medium carbon levels sit around .4-.7% and a high level of carbon is considered to be anything about .8%.

Chromium: The first line of defense against corrosion and a requirement to be in the stainless steel club. Any steel with a content of 10.5% of chromium or more is considered to be stainless steel.

Cobalt: Used to increase the blade’s rigidity.

Copper: Helps to combat corrosion but usually in trace amounts to avoid that copper-looking patina.

Manganese: This is used in small amounts to add strength and hardness but with too much and you’ll create brittleness.

Molybdenum: This material drastically increases the steel’s resistance to heat which allows for more options in machining and forging. You’ll usually see the very top tier steels using this to achieve special manufacturing processes that increase hardness without reducing corrosion resistance.

Nickel: In small amounts, nickel can aid in the manufacturing process by making the steel easier to weld and form while also increasing the final product’s durability of the blade during abuse.

Nitrogen: Nitrogen sometimes takes up some of the space carbon would have and by doing this, the blades anti-corrosion defense gets a small boost and the blade typically has a longer lifespan. Adding nitrogen may also aid in special manufacturing processes as it changes how quickly the steel hardens.

Phosphorus: This is used to increase resistance to corrosion and add overall tensile strength when there is a low amount of carbon present.

Silicon: Present in all steels in small amounts, silicon helps bind the materials together during manufacturing and acts as a deoxidizer.

Sulfur: Sulfur is typically added to steel that is especially hard to work with, making it easier to manage and manipulate at the cost of some final overall blade toughness.

Tungsten: Used to create extremely fine grain steel material by aiding in the formation of carbides. This increases the blade’s resistance to heat and also raises the final product’s Toughness.

Vanadium: Acting similarly to tungsten, this is used to create fine grain steel and ensures those grains remain small throughout the entire manufacturing process.

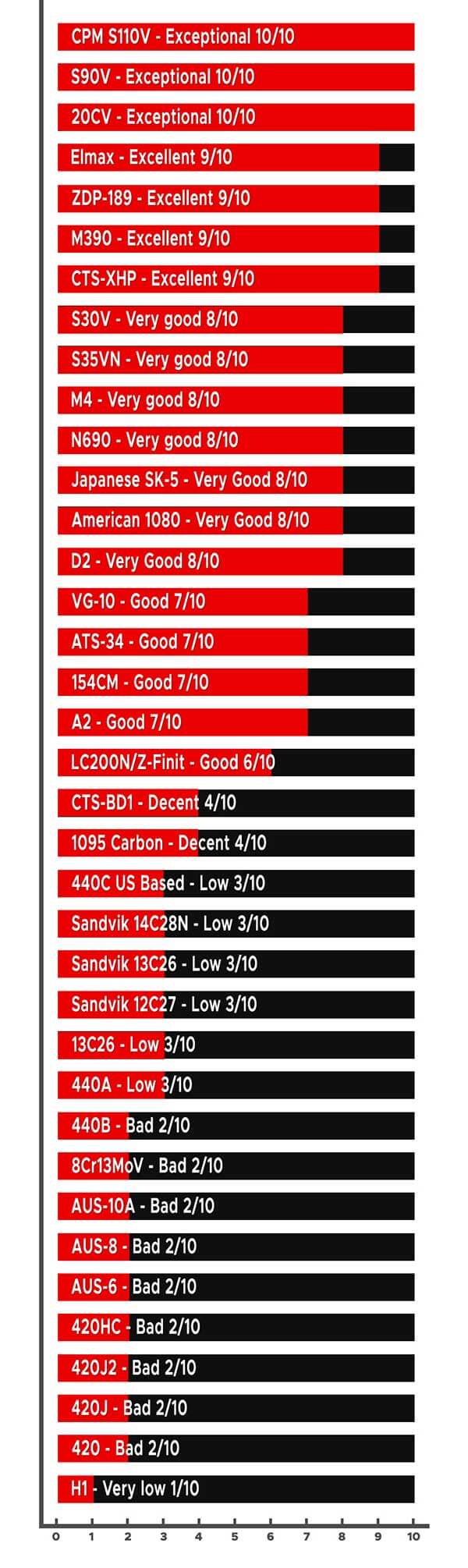

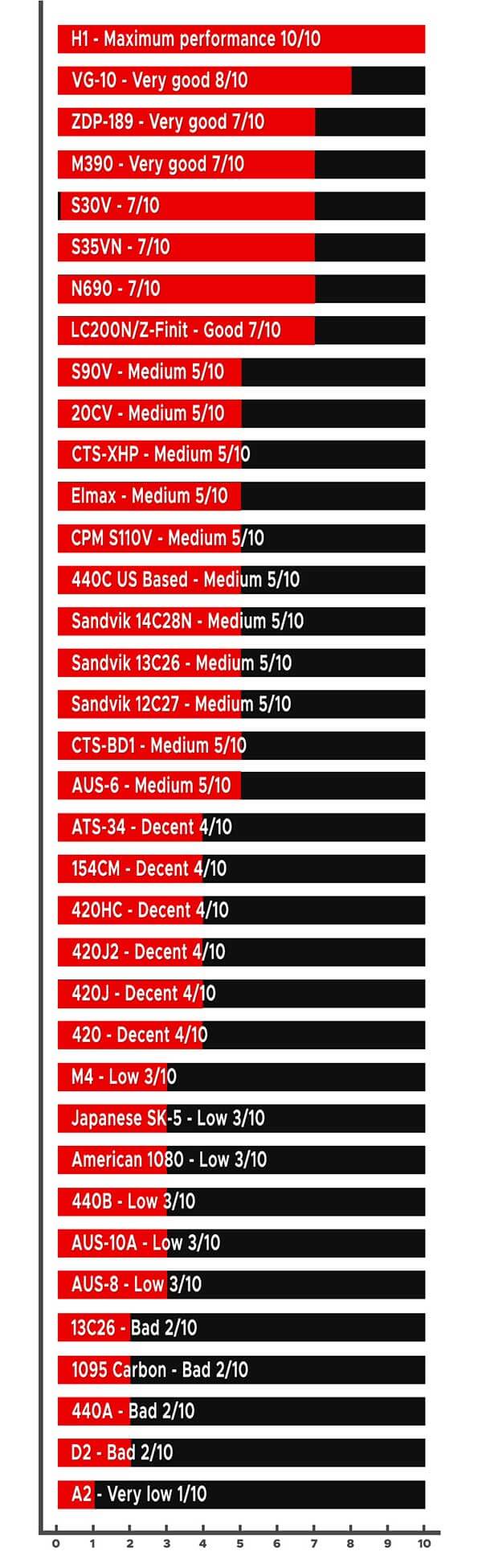

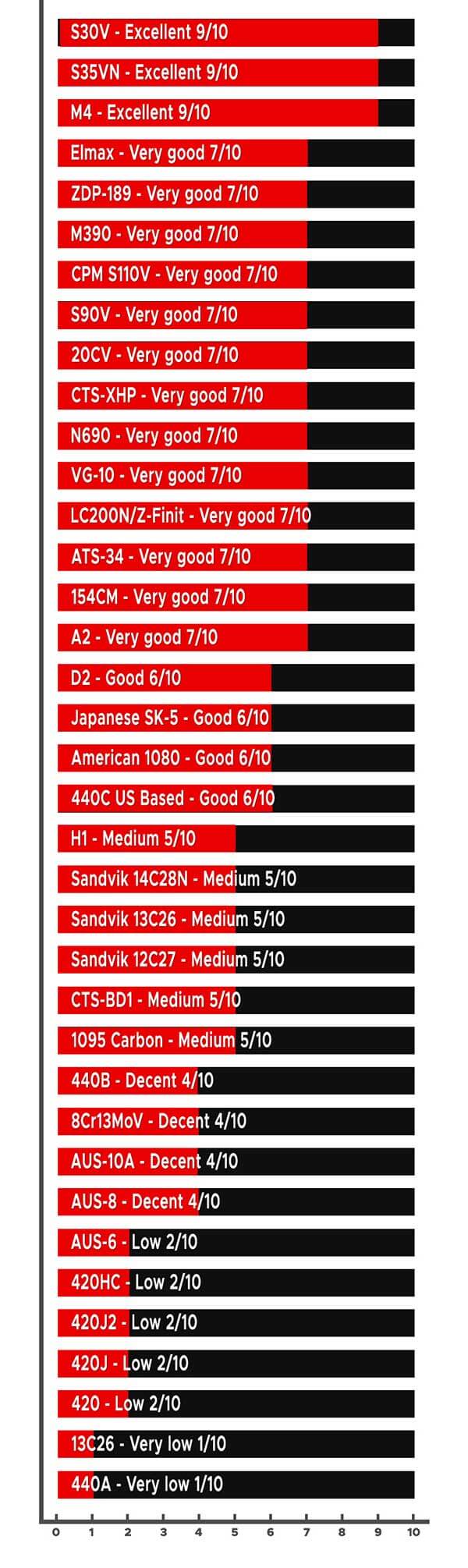

Knife Steel Charts

Edge Retention Comparison Chart

Sharpening Difficulty Comparison Chart

Steel Toughness Comparision Chart

Corrosion Resistance Comparison Chart

Let us know if you have any questions or comments below!

Popular Posts

I tried most of your links to these and there are out of stock or unsure of re-supply. However this is the best article on knives I have ever seen.

Thank you for writing this!