This site contains affiliate links. As an Amazon Associate, I earn a commission from qualifying purchases at no extra cost to you. Full Disclosure Here.

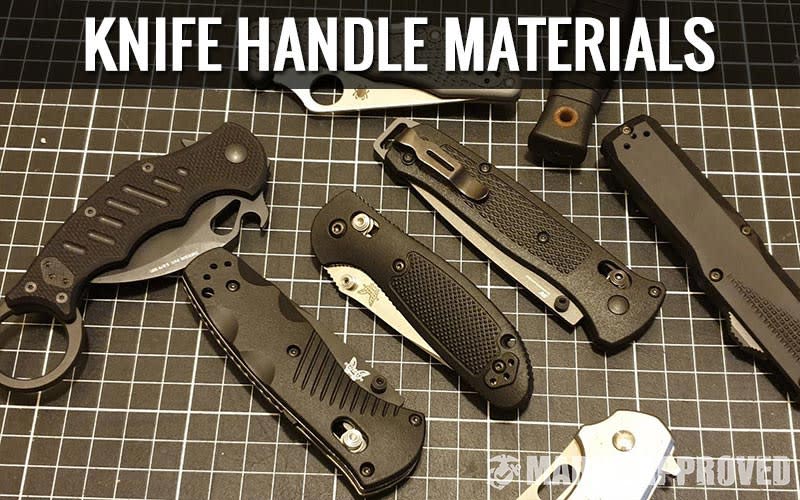

We have covered a lot of the basics when it comes to knives here on Marine Approved but we haven’t quite touched on the part of a knife that you actually touch the most! In this guide, we’ll be covering everything you need to know about knife handle and knife scale materials.

The technology behind our favorite pocket knives has really come a long way, and it’s easy to focus on the blade as that’s the business end of your trusty tool but if you’re an avid knife operator, then you know that grip and comfort are essentially just as important as the cutting surface of your knife. Powdered Metallurgy and locking mechanisms that could hold a car are super cool to talk about but knife scales and knife handles have made leaps and bounds with some pretty interesting technology and design.

Before we get started, I just want to make sure we have some of the basics covered. First and foremost, if you’re new to knives, the difference between scales and handles may be a bit cloudy. For those of you who want to skip ahead to a specific section, use the table of contents below.

What’s the difference between a knife handle and a set of knife scales?

Well, a knife handle is typically referred to as a single piece that is either molded or connected somehow to the knife’s tang.

Knife scales come in two pieces and clasp themselves around the tang of the knife.

These two are often used in place of each other on forums and in general knife-talk, but in reality, you should know the difference and you should have an idea of which you prefer before making a new knife purchase.

In some cases, some knife handle materials will perform better or be exclusively used as a knife handle or as knife scales. A good example of this would be bone because you don’t typically find bone scales since a bone is stronger as one single piece and is often difficult to break down into two perfectly symmetric pieces.

Why should you care about what material is wrapped around the tang of your knife?

For starters, the material is mostly going to impact the aesthetic and appeal of the knife, but more importantly, the material the knife handle consists of is going to determine a myriad of characteristics for the knife. Some of these characteristics include the performance and feel of its grip, usability in water, cost, corrosion resistance, weight and balance of the knife, and durability. Every knife handle material has its pros and cons which we will do our best to outline as we go through the list of knife handle and scale materials down below!

What’s the best material for a knife handle or knife scales?

There is no “best knife handle material” but there are materials that are certainly better for certain types of use cases than others. The handle or scale material that you should choose to purchase and use is largely going to come down to your budget, your taste in design, availability, the ergonomics of the material, and the tasks you plan to use the knife with.

A lot of people who are purchasing a knife for the first time will often overlook the handle material and instead choose a knife that looks appealing or has the steel type they prefer. Although you might get lucky and end up with a material that performs great anyways, it doesn’t hurt to understand each of the characteristics of a knife and narrow down your options to just a few that specifically meet your demands.

After you read through this guide on the available knife handle and knife scale materials, you’ll want to make sure you check out our other guides that outline and explain various other characteristics you’ll want to be aware of when it comes to knives. Those guides include a breakdown of the most popular steel types found in pocket knife blades as well as a knife shapes guide to aid you in getting a blade in the correct shape.

Here Are the Different Types of Knife Handle Materials

In this section we will breakdown the most common knife materials.

Category One: Synthetic/Plastics/Polymers

1. DuPont Zytel Fiberglass Reinforced Nylon (FRN) / Glass Filled Nylon (GFN) / Fiber-Reinforced Copolymer (FRCP)

Description: Zytel is a nylon resin, developed by the well-known chemical company DuPont. It’s a synthetic material used in many applications due to its resistance to heat, stiffness, and abrasion-resistant properties. Although Zytel materials can be found in a wide range of applications from automotive engine components to mobile electronic devices, it’s quickly become a favorite among knife enthusiasts because it offers a relatively low cost but high performing solution to creating an excellent grip on any range of knives from everyday carry (EDC) to kitchen blades.

Many knife manufacturers today are equipping their blades with Zytel grips because the material is mass-produced, has high availability, and is relatively easy to work with. Zytel handles and scales can be configured in virtually any size or shape which gives the knife manufacturer a lot of options and tolerance.

Just as a side note, FRN and GFN are the same and Zytel is simply the brand name for a specific FRN made by DuPont. FRCP is essentially the same as FRN/GFN but has a slightly lower melting point but is a tad bit harder. In the world of knives, the differences are negligible.

Cost: Zytel can be manufactured in bulk and easily machined into the desired shape and consistency making Zytel knife scales a great bang for your buck kind of material. In relation to most other materials used for knife handles and scales, Zytel is one of the cheapest but also one of the highest performing in terms of durability.

Durability: Zytel handles are among the most versatile and durable handles available today for knives.

Zytel is manufactured using high heat (600F) injection molding with polyamide nylon resins to create a handle that is, under normal typical use of a knife, essentially indestructible. Most knives will have their locking mechanism fail or their blades fall apart from wear and tear long before a Zytel handle needs replacing. While some handles like wooden handles have a lifespan of just a few years, Zytel handles under normal conditions should hold up for many decades and appear basically the same as they do when they are brand new.

Corrosion Resistance: Zytel scales and handles do not rust and are capable of being used in contact with salt water with no chance of corrosion resistance whatsoever.

Pros:

- Extremely high bang for your buck since Zytel is cheap and easy to manufacture

- Encompasses extreme resistance to heat and cold as well as complete resistance to corrosion

- After high heat treatment, Zytel is a material that impeccably impact resistant and overall very tough

- Zytel handles are among the lightest handles you’ll find for knives and since they are also very durable, this makes these handles some of the best performing for the weight

- Zytel is a maintenance-free knife handle material and hardly shows damage or aging

Cons:

- Zytel suffers from less overall grip and comfort than what you would find with a few of the other polymer-based grips like G10 or Grivory.

- Although Zytel scales and handles don’t have appearance changes with age, they initially don’t look very high quality and may often feel like a cheaper, lower quality plastic when in fact, that’s not the case when it comes to performance

- Zytel is manufactured by one company, DuPont, so it might be fair to make the argument that its supply may be cut off at the whim of one centralized company, although extremely unlikely in the near future (there are other manufacturers of FRN/GFN, just not Zytel specifically)

Types of Knives Commonly Utilizing This Material:

- EDC and pocket knives

- Combat or survival knives

- Kitchen knives

- Hunting/Fishing knives

Marine Approved Example: Spyderco Matriarch 2

2. High-Pressure Thermoset Plastic Laminate (G10) AKA Garolite

Description: G10 material consists of several layers of glass and nylon stacked and soaked in epoxy resin under compression and heat which creates a hard fiberglass laminate composite. G10 is an excellent replacement for metal-based knife handles because it’s much lighter with similar strength and durability but encompasses the potential for much greater levels of grip. G10 is often known for its extreme grippy texture. Carbon fiber is a little stronger than G10 and a little lighter since it uses carbon fabric instead of fiberglass but is a bit more costly and time-consuming to manufacture.

G10 allows a brand much more control over its creative processes. G10 comes in a myriad of colors, shapes, sizes, and overall seems to have more flavor to offer the knife world than competing synthetics. Aside from decent aesthetics, G10 scales are well-known to be just as impact resistant as carbon fiber, FRN, or any other polymer-based knife scales.

Remember, just like most of the other synthetic options on this list, the quality of G10 will differ from brand to brand and even from model to model in many cases. The quality of resin used to create G10 will generally vary in quality too, determining the degradation and overall toughness, but in most cases, G10 performs right on par or perhaps even better than most other knife scale options.

Cost: G10 is a relatively cost-efficient material that encompasses excellent performance to cost ratio.

Durability: G10 is an extremely durable synthetic material that should last several decades under normal use. Less durable than stainless steel or titanium (but cheaper) and more durable than Micarta, G10 is in a sweet spot that makes it appealing to many of the top knife brands.

Corrosion Resistance: G10 contains no metal and as such, it will not corrode, soften, or rust in any way.

Pros:

- Widely known for its excellent texturing and grip

- Resists environmental factors and impact quite well

- Has more aesthetic options than most other handles types

- It will last significantly longer than most metals, bone, or wood handles and will not shatter

- G10 can be manufactured to be smooth or heavily textured

Cons:

- Has slightly less UV resistance than some other synthetic options

- Feels cheaper than it performs in the hand

- G10 often appears like cheaper plastic when in fact, it’s not

- A heavily used G10 handle might expose fiberglass which could cause slight skin irritation (this is very unlikely with modern high-quality G10 handles)

Types of Knives Commonly Utilizing This Material:

- EDC and pocket knives

- Survival knives

- Hunting and fishing knives

- Kitchen knives

- Combat knives

Marine Approved Example: Benchmade Bushcrafter 162

3. EMS-Grivory (Griv-Ex)

Description: Grivory is another thermoplastic polyamide manufactured via injection molding similar to Zytel created by the company EMS-Grivory. Cold Steel coined the term Griv-Ex, however, this really is just a fancy way of indicating they use Grivory handles and knife scales. The polyamide Grivory is extremely resistant to heat and impact and, like Zytel, is resistant to corrosion and warping and encompasses a lifespan far greater than most metallic or wooden handles.

Grivory handles and scales are newer than Zytel and use a semi-crystalline structure to create a very strong and durable material that, in theory, is stronger overall than Zytel is. At the end of the day, most of these fiberglass reinforced nylon polymers are relatively similar with the main defining characteristic being that they are manufactured by a different company.

Grivory is a thermoplastic and make no mistake, in the hand it does feel like a rather cheap plastic. Thermoplastics garnered a reputation of not having that great of a grip, however, nowadays, some of the high-end knife manufacturers are equipping their knives with thermoplastic grips like Griv-Ex that have a textured pattern, like a diamond pattern, that offers pretty good grip even when wet.

Cost: Grivory is manufactured in bulk and is often used by Cold Steel and other knife manufacturers specifically because of its high performance to low-cost ratio making Grivory handles rival Zytel handles in terms of excellent value.

Durability: Grivory is another excellent performer with incredible resistance to the elements and overall great toughness. Any of these thermoplastics should last several decades even through rugged everyday use and will likely outlast the blade they are attached to.

Corrosion Resistance: Grivory hosts complete resistance to corrosion since it’s thermoplastic and contains no metal.

Pros:

- Grivory is an excellent cost to performance choice and can be found on both high end and low-end knives

- Grivory is injection molded, meaning it can be molded into virtually any shape and any size with specific texturing

- Grivory will outlast many of the other handle materials such as wood and metal handles

Cons:

- Grivory, like most thermoplastics, may feel cheap and undesirable in the hand despite having excellent performance across the board

- It is very difficult to get a premium look and feel finish

- It is manufactured by one sole company

Types of Knives Commonly Utilizing This Material:

- EDC and pocket knives

- Survival knives

- Combat knives

- Hunting/Fishing knives

Marine Approved Example: Cold Steel 4 Max Scout

4. Phenolic Resin Thermoset Linen/Canvas/Fiberglass (Micarta)

Description: Micarta can vary drastically from brand to brand and even from knife to knife because micarta isn’t really one thing, but more so a group of handles that consist of multiple different materials soaked and thermoset in plastic. Micarta can be made from canvas, linen, burlap, carbon fiber, fiberglass, and even paper!

In most cases, Micarta will seem quite similar to many other synthetic handles and is often mistaken as such. For example, fiberglass micarta is almost indistinguishable in both performance and appearance to G10 to the untrained eye.

Cost: Since Micarta can be developed with a myriad of different materials, the cost will be dependent on what materials are involved and what process the micarta is being manufactured by. As a general note, micarta is generally inexpensive.

Durability: Micarta, when it was introduced to the public sometime in the early 1900s, was dubbed a replacement for steel. Of course, stainless steel knife handles and micarta handles are going to vary greatly but at the end of the day, a micarta handle is going to offer top-class durability and resistance to weathering.

Corrosion Resistance: Micarta may contain many different materials but it does not contain metal and as such, will not corrode.

Pros:

- Micarta has been around a very long time and has been heavily researched and improved upon

- Micarta was dubbed a replacement to steel as a testament to its strength and performance

- Micarta is relatively inexpensive and does not have a single company monopoly for supply

- One of the easiest materials to create stunning and artistic finishes

Cons:

- The material quality can vary significantly between brands with low-quality micarta handles sometimes underperforming

Types of Knives Commonly Utilizing This Material:

- EDC and pocket knives

- Kitchen knives

- Camping knives

- Combat knives

- Hunting and fishing knives

Marine Approved Example: Benchmade Proper 318

5. Carbon Fiber / Woven Synthetic Fiber

Description: Carbon fiber knife handles consist of a resin-soaked weave of carbon fibers which, when heat treated, becomes extremely strong and durable yet remaining rather lightweight.

Cost: Carbon fiber knife handles are going to cost a premium compared to other synthetic handle materials. Carbon fiber handles are excellent, but at the end of the day, the advantages they provide make them more of a “want” than a “need”. Carbon fiber handles are often stunning in appearance because, well, carbon fiber looks pretty dang cool, especially when the light reflects off of different parts of the weave.

Durability: Carbon fiber is well-known to have a tensile strength at levels much higher than most other synthetic handles but suffers in popularity due to being a bit more expensive and not as widely available as synthetics like G10 or FRN.

Corrosion Resistance: Carbon fiber does not rust or corrode and has some of the best resistance to weathering of any knife handle material.

Pros:

- One of the lightest materials to be used in knife handles

- Contains best in class weight to strength ratio performance

- Looks super cool and let’s be real, looking cool is what matters, right?

Cons:

- Carbon fiber is a rather lengthy process and is more expensive than most other synthetic handle materials

Types of Knives Commonly Utilizing This Material:

- EDC and pocket knives

- Combat knives

- Hunting and fishing knives

- Camping knives

- Survival knives

- Kitchen knives and any cutlery

- Showpieces and collectors knives

Marine Approved Example: Spyderco Chaparral Prestige

6. CF-Elite (Benchmade Exclusive)

Description: CF-Elite is Benchmade’s version of carbon-based polymer handles but is roughly 50% stiffer and 17% lighter than traditional fiberglass-based polymers. This allows for a handle that is thinner, contains less overall material, but performs just as good or better than regular glass-filled polymers.

In our experience, A CF-Elite handle feels a lot like a regular GFN but has noticeably less flex to it and about the same look and feel both aesthetically and in the hands.

Cost: CF-Elite (Carbon Fiber Reinforced Nylon) handles are only found on Benchmade premium products and even their knives with traditional GFN handles are expensive so I’d say that although the handles themselves likely aren’t that much more costly to manufacture than a regular GFN handle, it’s going to cost you quite a bit to get one no matter what.

Durability: The same as most synthetic knife handles but a tad stiffer, making them stronger during normal use but more prone to snapping under extreme forces.

Corrosion Resistance: CF-Elite contains no metal and is purely synthetic so it will not rust or corrode.

Pros:

- Stiffer and lighter than other synthetic knife handles

- Uses carbon in place of fiberglass to get what is essentially the best of both a fiberglass filled handle and a carbon fiber handle

Cons:

- Only found on Benchmade products which may be out of some peoples budgets

Types of Knives Commonly Utilizing This Material:

- Benchmade pocket knives

Marine Approved Example: Benchmade Bugout 535BK-2

7. Styrenic Block Copolymer (SBC) AKA Kraton / Kray-Ex or Thermorun

Description: Kraton, manufactured by Kraton Polymers, and Thermorun, manufactured by Mitsubishi Chemicals, are similar plastic rubberized polymers that provide excellent grip without much need for artificial texturing. You may be familiar already with a handle made out of these polymers as they are commonly found on Ka-Bars, Fallkniven, Cold Steel, and several other major knife brands.

Kraton handles often get a bad reputation because the quality between brands that utilize a handle of such polymer can vary drastically. For example, the Fallkniven MC-1 has a Kraton handle that can resist harsh chemicals and will last a very long time before degradation but low-quality Kraton handles can become “melty” and sticky after just a few years of usage creating a horrible feeling and even sometimes rubbing off on your hands.

It goes without saying that if you want a rubberized handle then you need to ensure you are purchasing a Kraton or Thermorun handle that’s attached to a rather high-quality knife in the first place.

These rubberized polymers are made from butadiene, isoprene, and styrene and are processed much like thermoplastics but behave more like a rubber compound. Kraton handles are typically a metal handle, generally stainless steel, wrapped in the Styrenic Block Copolymer compound.

Cost: These handles are generally on the lower end of cost, however, I would advise only choosing SBC handles that come from highly reputable, high-end knife brands to begin with, so it may be a bit expensive to get yourself a quality knife with an SBC handle that will last and endure.

Durability: SBC handles are very impact resistant and perform very well despite what temperature it is outside, however, the quality of SBC handles varies greatly from brand to brand. Some low-tier SBC handles have issues with fluid absorption and degradation and all SBC handles suffer from puncture damage which may allow them to begin tearing or separating from the base of the handle.

Corrosion Resistance: SBC polymers do not contain metal themselves and as such, cannot rust or corrode.

Pros:

- Extremely grippy without the need for texturing

- Grip performance doesn’t change despite the temperature

- Very comfortable when brand new

- General resistance to weathering and impact

Cons:

- Seems to cause excessively sweaty hands, more so than other polymers

- Low-quality Kraton handles can degrade and become sticky

- The inside of a tire is the only appearance possible with Kraton handles

- Long exposure to fluids may cause absorption

- More difficult to clean than most other synthetic handles

Types of Knives Commonly Utilizing This Material:

- Combat knives

- Utility knives

- Survival knives

Marine Approved Example: Fallkniven A1

8. Valox (Thermoplastic Polyester High-Density Resin)

Description: Valox was originally created by General Electric but was passed overseas during the sale of General Electrics Plastics division to Saudi Basic Industries Corporation in 2007. Like many polymers, the quality may vary depending on the brand utilizing the material. Benchmade is a popular brand utilizing Valox and the finish of these polymer handles is very impressive.

Valox has a more shiny and less porous appearance and texture than any of the other polymers on this list, thus making it appear of higher quality and encompasses an overall better surface appearance.

Valox, for the most part, is used in part to create a smooth and high-quality polymer finish where other polymers often appear more textured and rugged. Think of Valox as the Cadillac of the polymer world, where the Cadillac may have similar performance to its GMC counterparts but has a slightly higher fit and finish with an overall higher quality appearance. Valox could easily be mistaken as FRN but in most cases, Valox is generally harder to the touch and smoother overall, but in terms of performance, the two are essentially the same, being lightweight, resisting aging and weathering, and performing overall very well.

Cost: Valox costs about the same as most other thermoplastics and is manufactured from injection molding on a large bulk scale, making them low cost and readily available.

Durability: Valox has very similar properties to FRN in terms of durability, meaning it’s got great resistance to weather and aging and should hold up even through heavy usage just fine.

Corrosion Resistance: Valox is a thermoplastic and as such, contains nothing that will corrode.

Pros:

- Encompasses a smoother and nicer finish than most other thermoplastics

- Is extremely lightweight but also extremely durable

- Should last longer than the blade it’s attached to

Cons:

- Still has a rather plastic-like feel which many find to be of low quality

- Is not nearly as popular as some other thermoplastics so the knives with Valox handle options are less

- Generally has a more slippery and smooth texture than G10, FRN, Micarta, etc (Could also be a pro depending on what you are looking for)

Types of Knives Commonly Utilizing This Material:

- EDC and pocket knives

Marine Approved Example: Benchmade Mini-Barrage 585BK

9. Acrylic/Plexiglass

Description: Acrylics and plexiglass found in knife handles are going to perform significantly lower than many of the other polymers and thermoplastics as they are extremely inexpensive. Knives with acrylic handles generally aren’t attempting to be workhorses but more so cheap collector type knives. The positive thing about acrylic is that it’s commonly used to create beautiful appearing handles and can often be used to imitate a much more expensive and appealing material.

Cost: Acrylic handles are extremely cheap and won’t be found on top tier knives. Making knife scales and handles out of acrylic is somewhat of a cheap artsy hobby for many knife enthusiasts!

Durability: Acrylic can perform a bit better than some of the knife handle materials on this list such as bone in terms of simply surviving a bit of abuse or a fall onto a hard surface but overall, acrylic is not nearly as strong nor as durable as something like G10, Grivory, or really any of the other synthetic handles on this list.

Corrosion Resistance: Acrylic has no metal compounds and as such, cannot rust or corrode.

Pros:

- Extremely cheap and easy to work with

- Can be used to imitate or recreate more exquisite or more expensive materials for showpieces

- Is commonly found and has a community of people making homemade acrylic handles

- Less prone to damage from impact than bone, marble, stone, and horn materials

Cons:

- Not intended to be used on knives that face constant heavy abuse

- Can be slightly heavier than other synthetic knife handle materials

- Generally smooth and contains less grip than textured thermoplastic materials

Types of Knives Commonly Utilizing This Material:

- Collectors/showpieces

- Cheap Stilettos

- Hobbyist knives

- Kitchen knives

Marine Approved Example: Gerber Jukebox

10. Paracord Wrapped / Tsukamaki

Description: This isn’t a core material because any knife with a paracord whipped handle is going to have a base such as stainless steel, titanium, some kind of wood, and even sometimes synthetic bases. Now, you could paracord wrap pretty much anything in theory but for the most part, nicely done paracord wraps are performed on knives whose handles original design was taking into account being wrapped in the first place, meaning they were essentially designed to be used in tandem with paracord.

Some people find paracord wrapped knife handles to be silly or useless but the truth is, there are a myriad of different reasons why you might want to grab a knife with a wrapped handle or perhaps wrap a knife handle that you already have. For starters, wrapping the handle with paracord is going to give an obvious boost to the thickness of the handle which, if you’ve found the handle to be worn down or too small for your hands, would make the knife far easier to use.

Secondly, the paracord wrapped around the handle of your knife could become a tool of its own that’s just as important as the knife. Using paracord in tandem with a survival or camping knife ensures you always have something to replace broken shoelaces with, create a bow drill for fire making, craft a makeshift bow for hunting, and many more other helpful use cases.

Tsukamaki is a flat type of corded wrap used on Japanese swords.

There are many different ways to wrap a knife handle in paracord. I found this list of 25 different methods on Paracord Planet to be particularly helpful.

Cost: Paracord is insanely inexpensive for how useful it is! You can find a thousand feet of 550 paracord for just twenty bucks on Amazon in any color you like!

Durability: I mean, you can tow your truck with it, check it out: https://www.youtube.com/watch?v=CELbLdngMaU&ab_channel=HandmadeByHeroes

Corrosion Resistance: Paracord has no metal so it has no potential to rust.

Pros:

- Makes the handle thicker

- Can be used as a tool

- Lightweight and very durable

- Cheap way to change or cover a worn or damaged handle

Cons:

- Might make the handle too thick for comfort

- May interfere with some sheaths

- Requires a small amount of time to learn the proper technique (It’s super easy, though)

Types of Knives Commonly Utilizing This Material:

- Survival knives

- Camping knives

- Hunting and fishing knives

- Combat knives

Marine Approved Example: CRKT Utsidihi

Category Two: Metals Used to Make Knife Handles

11. Titanium

Description: Titanium is going to be our premium option in terms of metal knife handle materials but as they become more popular, especially in pocket knives, the price of titanium is starting to slip down from premium tiers into more affordable options.

Titanium has really low density but an extremely high level of tensile strength making it one of the best metals in terms of strength to weight performance. The most popular titanium used in knife handles is called Ti6AI4V which is one of the strongest and most common types of titanium alloys. In general, titanium is about 40% lighter than stainless steel but just as strong as the best steels out there which makes it a very attractive material to use, especially for pocket knives, anything EDC, and camping knives.

Titanium is the way to go if total strength and performance per dollar are your main concerns and hey, many people find titanium to be exceptionally beautiful and easy to create a lot of different patterns and designs.

Cost: Titanium is the most expensive commonly used knife handle material in terms of metals

Durability: Titanium is far harder and more resistant to damage than both stainless steel and aluminum and encompasses a superior tensile strength and a better weight to performance ratio making titanium the most durable metal to use for a knife handle

Corrosion Resistance: Titanium is far more resistant to corrosion than stainless steel and for most people, will be plenty resistant to weathering

Pros:

- The obvious choice in terms of performance and durability

- Starting to become very popular and offered by many brands

- When used by a reputable brand, the finish can be astonishingly beautiful and highly sought after

- Titanium knife handles are becoming very much so affordable

- Titanium does not feel as cold as any other metal making it much more comfortable to use in cold environments

Cons:

- Traditionally more expensive than other knife handle materials (prices are dropping)

- More prone to surface scratching than stainless steel

Types of Knives Commonly Utilizing This Material:

- Diving knives

- Camping knives

- EDC or pocket knives

- Butterfly knives

- Combat knives

- Survival knives

- Backpacking knives

- Kitchen knives and cutlery

- Showpieces and collectors knives

Marine Approved Example: Benchmade 85 Billet TI Bali-Song

12. Aluminum

Description: Aluminum is known for its decent cost to performance ratio and although it has a rather low density on its own, aluminum is a light and cheap enough metal that it can be used in large quantities and as such, to make thick and durable knife handles that are relatively lightweight. The most common aluminum you’ll find on knife handles is T6-6061 which is aluminum that’s used to make aircraft due to its high tensile strength but lightweight properties.

Cost: Aluminum is a very low-cost material that can be found in any price range of knives and is one of the cheapest metals in general and much cheaper than titanium or steel knife handles.

Durability: T6-6061 is used in the production of aircraft due to its ability to twist and bend but never break. Aluminum isn’t a particularly rigid material but it’s extremely snap-resistant and when applied in thick layers, can be quite hefty and strong despite feeling relatively lightweight compared to steel.

Corrosion Resistance: Aluminum is often used specifically because of its ability to resist rusting and as such, has a decently high level of corrosion resistance, especially T6-6061 aluminum.

Pros:

- Aluminum is cheap, lightweight, abundantly available, and used by many knife brands all over the world

- Aluminum can be texturized and anodized for a multitude of textures, designs, and physical characteristics

- Aluminum is extremely resistant to weathering and corrosion (although less than titanium)

Cons:

- Can be uncomfortable to use in cold weather

- Can sometimes be slippery when wet

- Can scratch

Types of Knives Commonly Utilizing This Material:

- EDC and pocket knives

- Kitchen knives and cutlery

- Survival knives

- Butterfly knives

- Combat knives

- Hunting and fishing knives

Marine Approved Example: Benchmade Phaeton

13. Stainless Steel

Description: Making stainless steel is quite easy, just take a regular steel alloy and mix it with a bunch of carbon, some chromium, and a little bit of molybdenum and you have an ultra-strong, ultra corrosion resistant strain of steel ready to withstand daily abuse, all without breaking the bank.

Stainless steel knife scales and handles are in an excellent spot considering price, weight, and performance but aren’t exactly the best in any of these categories considering aluminum is cheaper and lighter and titanium is stronger but stainless steel still reigns supreme as one of the most popular knife handle materials today because its simple and extremely abundant.

Chances are, the blade your knife handle is connected to is already steel, so it makes perfect sense to use steel for the handles, too! Of course, the two are almost always going to be different types of steel. The steel used in your blade has to be decently hard to resist damage but not so hard that it becomes too brittle to hold an edge or sharpen but your knife handles don’t have these restrictions so they can be made out of a myriad of different types of steel.

Stainless steel knife handles and scales are usually pretty slippery and awfully cold in the winter so to circumnavigate that, many brands will apply a rubberized coating or a sort of wrap, like leather or paracord.

Cost: Since there are so many different stainless steel options it’s hard to say what a specific knife handle will cost. Usually, cheaply made blades like 1095 stainless steel will have a similar quality handle, whereas a high-end blade, something like CPM-S30V, might have much better steel in its handle too.

Durability: Stainless steel knife handles are extremely durable but they do have a particular tradeoff. The more chromium added to the steel alloy in its production means it will have better resistance to corrosion but that takes away from the amount of carbon, making the steel softer. Not all stainless steel is created equally so read up on the specific type of stainless steel before making a purchase. This fact goes along with the blade of your knife as well!

Corrosion Resistance: Stainless steel can come in a very wide variety but as a general rule of thumb, stainless steel is decently resistant to corrosion. The more chromium added to the steel alloy, the less it will rust but the softer the stainless steel will be.

Pros:

- Cheaper than titanium handles

- Relatively inexpensive but with high durability and strength

Cons:

- Heavier than aluminum and titanium knife handles

- More expensive than aluminum

- Hard to texture and can be very slippery

Types of Knives Commonly Utilizing This Material:

- EDC and pocket knives

- Butterfly knives

- Survival knives

- Camping knives

- Hunting and fishing knives

- Kitchen knives and cutlery

- Showpieces and collectors knives

Marine Approved Example: Kershaw Misdirect

Category Three: Animal Product Knife Materials

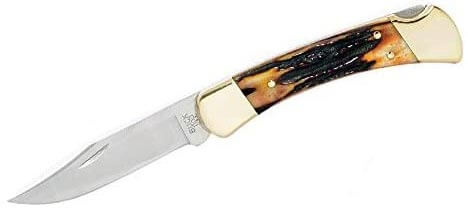

14. Stag (Deer Antler)

Description: Stag is deer antler and, well, people use it because they like it and it has thousands of years of history! Of course, back in the day before we had thermoplastics and polymers, stag knife handles were as good as anything else. The stag is relatively hard, is resistant to weathering better than most wood, looks pretty awesome, and it’s readily available to those near a deer population.

Nowadays you typically find stag being used in knife handles for one of two reasons, the first being personal affection towards its appeal and that it’s a fun and easy material to make a DIY knife handle. The best knives on the market in terms of price and performance are not going to be using stag handles, but this doesn’t mean they are useless as they are very much so good knife handles, even if they don’t last decades like a thermoplastic or are light and nearly indestructible like titanium.

Some people may consider stag being used as a knife handle to be cruel or inhumane, but unlike taking the horns from an animal and leaving them defenseless, deer will shed their antlers every year, meaning stag can be obtained from the deer population where otherwise the antlers would simply be left to waste on the forest floor. This usually happens around March or April so if you’d like to try your hand at making your own knife handle, get out there and look around for gifts given to us by nature (or buy it on eBay)!

Check out this video to learn how to make your own antler handles!

Cost: Cost is kind of a weird conversation here. On one hand, the price can vary quite a bit depending on what animal and region the stag is from, what condition it’s in, what physical characteristics it has, and its size. You could find custom-made stag handles on knives worth thousands of dollars but you could also buy some cheap stag off of eBay for just a couple of bucks and make your own handle.

Durability: Stag as a natural material is pretty dense and relatively strong but it does have a few drawbacks. Sunlight and extreme heat or simply being left in really dry air can cause the stag to crack from dehydrating. You can apply a special hydrating wax that, even in hot and dry environments, can see a good stag handle lasting at least a couple of decades.

Deer smack each other head-on at something like 40 mph several times and, if any at all, there may be a small chip or scratch, leaving them to continue their battle, so to put that into perspective for a knife owner, stag handles can handle quite a bit of abuse and can certainly be used in most of the same situations that any other handle material could be used.

Corrosion Resistance: Stag is a natural material and contains no metal so it cannot corrode.

Pros:

- Can be found for free anywhere there are deer

- Is a naturally occurring and renewable resource

- Has a lot of creative and artistic use and techniques

- Is very popular in the knife collecting community

- Has been tried and tested for literally thousands of years

Cons:

- Can dry and crack under intense heat

- The best stag handles can cost thousands of dollars

Types of Knives Commonly Utilizing This Material:

- Showpiece and collectors knives

- Hunting and fishing knives

- Pocket knives

- Camping knives

Marine Approved Example: Buck Knives 110 Amber Stag

15. Tusk Handle

Description: Using the tusk of an animal such as an elephant or walrus as a knife handle is one of the oldest methods of knife handle making known to man and in 2016 elephant ivory became pretty much completely illegal to trade in the US, the UK, and many other countries around the world. The laws are pretty muddy and we won’t even attempt to lay them out here so if you want to make or buy a knife handle with ivory, it is up to you to make sure you are operating within the law.

Like stag, ivory is extremely dense, very strong, and resists weathering decently well. Ivory is often sought after for its visual effects and is/was very popular in the knife collecting world but is very much so usable due to its excellent performance.

Cost: Ivory is now banned from being traded in most countries our readers are from but if you can buy a legally acquired knife with an ivory handle, they are generally going to be quite expensive.

Durability: Ivory performs about the same as stag in a general sense and can be prone to drying out and cracking under extreme conditions. Remember that elephants put thousands of pounds of force behind them, smacking each other around, and at the end of the day, there might be a few dings and scratches, so it’s unlikely dropping your ivory-handled knife is going to harm it.

Corrosion Resistance: Ivory is natural and contains no metal so it does not rust or corrode.

Pros:

- Many knife collectors appreciate ivory’s appearance and physical properties

- Ivory is extremely hard, dense and resistant to impact

Cons:

- Ivory is illegal for trade and comes with major ethical and moral consequences (we do not support the trade or harvesting of ivory)

Types of Knives Commonly Utilizing This Material:

- Collectors knives

- DIY knives

16. Bison / Buffalo Horn

Description: Buffalo have been hunted by our ancestors for thousands of years and most tribes that followed the buffalo had a mantra of using each and every part of every kill. The hides went into Tipi construction, leather making, and drums, the teeth went into tools and jewelry, the bone was crafted into weapons, and the horns used to make handles for said weapons and tools.

Nowadays we don’t really rely on buffalo horn for EDC or heavy use cases but many collectors still enjoy buying or even making their own buffalo horn knife handles.

Cost: Buffalo horn can vary greatly in cost depending on many factors but is generally lower cost

Durability: Buffalo horn can dry out and crack and like stag, can be rehydrated and treated with wax or oils. Aside from that, buffalo horn is a bit softer than stag or bone which made them a lot easier to work with and fasten to a blade. Although this softness makes them a bit more prone to scratching, buffalo horn is actually less prone to breaking or snapping than antler or bone.

Corrosion Resistance: Contains no metal so it has no chance of corrosion

Pros:

- Found to be aesthetically pleasing by many collectors and enthusiasts

- Used for thousands of years as a very viable knife handle material

- Easier to work with than stag

Cons:

- Can crack in arid and dry environments

Types of Knives Commonly Utilizing This Material:

- Showpiece and collectors knives

- Camping knives

- Hunting and fishing knives

- DIY knives

Marine Approved Example: Case Cutlery XX WR Buffalo Horn Hunter BH23-5

17. Bone

Description: Bone is a hard and dense material that is relatively easy to work with and is usually a byproduct of any kind of hunting. Although not nearly as good as a synthetic handle, bone has been used in tandem with blades as a handle for thousands of years.

Today, bone is mostly a novelty in the knife world as it’s easy to DIY with, especially for hunters that have already harvested bone and likely have little other use for it, and in the world of knife collectors where certain bone handles fetch high prices due to exquisite appearance or rarity.

Cost: The cost will entirely depend on where you get it and what kind of bone it is.

Durability: The actual performance of the bone is going to depend mostly on what animal it came from, what bone it is, how thick it is, and how it was treated and cared for by the craftsman. Bone can dry out and shrink as well as crack in dry environments but this can be mitigated with special oils and wax.

Corrosion Resistance: The bone will not corrode as bone does not have any metal.

Pros:

- Bone is readily available and renewable

- Bone can be had really cheap, especially bone from cow or any mass harvested animal

- Bone is a favorite among DIY handle makers because it’s relatively available and easy to work with

- Can be dyed for basically any color configuration

Cons:

- The bone will dry out and crack in hot environments

- Can be slippery to use when wet without texturing

Types of Knives Commonly Utilizing This Material:

- Showpieces and Collectors knives

- DIY knives

Marine Approved Example: Randy Knifes RA-9002

18. Leather

Description: Leather comes from animal hide and has been a resource used by humans for an insanely long time to create shelter, clothing, baskets, backpacks, and of course, handles for our knives!

Leather handles aren’t insanely popular nowadays because it’s a far softer material that is guaranteed to wear down much quicker than bone, stag, or any kind of handle made from synthetics or metals. Leather does look amazing and does appeal to a lot of knife collectors and enthusiasts and it is a nice material in the hands that can be pretty comfortable if done correctly.

Just like paracord, there are also knives that can simply have their handles that consist of other materials wrapped in leather where it’s being used as a replacement, to create a thicker handle, or to simply have a long piece of leather on hand in case you need it on the go.

Here’s a quick little tutorial on how to make a leather handle for your knife!

Cost: The cost will depend on the type and quantity of leather you get but in general, leather is a rather inexpensive material for knife handles and handle wraps

Durability: Leather is going to be one of the least durable materials on this list but a high-quality leather wrap that isn’t left to dry out should last several years before being easily replaced

Corrosion Resistance: Leather doesn’t corrode but it will weather faster than any other material on this list

Pros:

- Leather is rather inexpensive and very easy to work with and DIY

- Leather can be used as a cheap way to cover an already worn or damaged knife handle

- Many knives that are purpose-built to be wrapped in paracord can also be wrapped in leather

- Leather can be made to create very aesthetically pleasing knife handles and is popular in the world of knife collectors

Cons:

- Leather just isn’t as resistant to wear and tear as metal or synthetic knife handle materials

- Needs to be replaced every few years and needs to be protected from dry and arid environments

Types of Knives Commonly Utilizing This Material:

- Showpieces and collectors knives

- DIY knives

- Hunting and fishing knives

- Camping knives

- Survival knives

Marine Approved Example: Ontario Knife Company 499 Air Force Survival Knife

19. Nacre (Mother-Of-Pearl)

Description: This iridescent looking material comes from the inside lining of the mollusk shell and is pretty much used solely for its aesthetic properties.

Cost: Mother-of-pearl costs about $15 per kilogram and is typically used in collector’s pieces so in terms of knife handles, it’s not exactly expensive but its properties as a knife handle aren’t exactly valuable outside of aesthetics either. Mother-of-pearl is nowhere near as expensive as actual pearls are.

Durability: Very low durability and typically not used on knives that would see abuse or extreme conditions as it has an extremely low hardness level.

Corrosion Resistance: This stuff comes from mollusks which sit at the bottom of the ocean or lakes so I think it’s safe to say they are pretty corrosion resistant!

Mother-of-pearl does not corrode.

Pros:

- Shiny and pretty

- An inexpensive way to be artistic while knifemaking

- Great for DIY showpiece projects

Cons:

- Extremely soft and brittle

- Not any good for a knife that will see abuse or harsh conditions

Types of Knives Commonly Utilizing This Material:

- Showpieces and collectors knives

Marine Approved Example: Case Cutlery White Pearl

Category 4: Woods Used in Knife Handles

20. Natural Wood

Description: Wood is a no brainer when it comes to making knife handles as it’s been the favorite choice since knives have existed.

Some of the most popular types of wood used for knife handles include Amboyna, California Buckeye, Cocobolo, Desert Ironwood, Lignum Vitae, Walnut, Hickory, Maple Burl, Birch Bark, and Red Oak.

Cost: Typically one of the cheaper options but the cost entirely depends on the type of wood and who is working with it.

Durability: Again, this will completely depend on what type of wood is being used and in most cases, will be less durable than stabilized wood and is always less durable than metal or synthetic knife handles.

Corrosion Resistance: Wood does not corrode but certainly can weather, warp, dry out, crack, discolor, and expand.

Pros:

- Can be visually appealing and encompasses a wide range of styles and designs

- Can be dyed and finished in a myriad of ways, also great for DIY

- Can be relatively inexpensive or extremely expensive depending on what you want

- Many options to choose from

Cons:

- Not nearly as good of an overall performer as synthetics or metal

Types of Knives Commonly Utilizing This Material:

- Showpieces and collectors knives

- Camping knives

- Survival knives

- Hunting and fishing knives

- DIY knives

- Kitchen knives

- Pocket knives

Marine Approved Example: Fallkniven Tre Kronor De Luxe Hunter

21. Stabilized Wood

Description: Stabilized wood is created by injecting layers of wood, typically softer types, by being superheated and injected with a polymer or phenolic resin under high pressure in a vacuum chamber. This process is similar to lamination and the end result is a treated and stabilized wood that is generally far more durable and resistant to weathering and damage than using unstabilized wood.

Wood is, by nature, very fibrous and porous which means it’s prone to cracking and splintering off. Stabilizing the wood essentially bonds the fibers together and fills in any gaps making the overall product much stronger more of a single piece than a bunch of natural fibers interlaced.

A huge advantage stabilized wood has over wood is that it has much less reaction to humidity, temperature, pressure, and doesn’t expand or contract nearly as much. Stabilized wood is also much more resistant to chipping although its finish can look unsightly from damage a bit quicker than traditional wood handles.

Some of the most popular brands of stabilized wood used for knife handles includes plywood based Dymondwood, Staminawood, and Pakkawood, but you can buy or even stabilize wood yourself! Check out this video to learn more about stabilizing wood.

A popular test many in the knife world employ to determine if a wood can be used as-is or needs to be stabilized is the “fingernail test”, where essentially if you can damage or pull up any of the wood just by using your fingernail, then it should be stabilized for use as a knife handle. A lot of different types of woods can accept stabilization except for some of the extremely oily hardwoods.

Cost: Stabilized wood is more expensive than regular wood due to the extra processing and materials involved in its production.

Durability: Stabilized wood knife handles are significantly more durable than traditional wooden handles.

Corrosion Resistance: Wood does not rust and stabilized wood certainly doesn’t either!

Pros:

- A massive increase in strength, durability, and resistance to weathering

- Pretty much any wood can be stabilized and used as a knife handle

- Stabilizing closes up the pores in the wood making it resist absorption resulting in a safer and cleaner knife when on food products or skinning

Cons:

- Costs more than its unstabilized counterparts

- Still isn’t as strong or durable as synthetic or metal knife handles

Types of Knives Commonly Utilizing This Material:

- Showpieces and collectors knives

- Survival knives

- Hunting and fishing knives

- Kitchen knives

- Camping knives

Marine Approved Example: Benchmade North Fork 15031-1

Thank you Corporal Wabo for another Excellent & comprehensive article!! It was very well done!